What is manual handling?

The term 'manual handling' or 'moving and handling' is defined as:

"The transportation or support of a load by human effort alone."

This effort may be applied directly, for example, pushing, pulling or carrying a load or indirectly using a rope or a lever.

In the Manual Handling Operations Regulations 1992 (as amended) (MHOR), the Regulations define manual handling as: "...any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or bodily force". The load can be an object, person or animal.

What are the UK Manual Handling Operations Regulations 1992 (MHOR)?

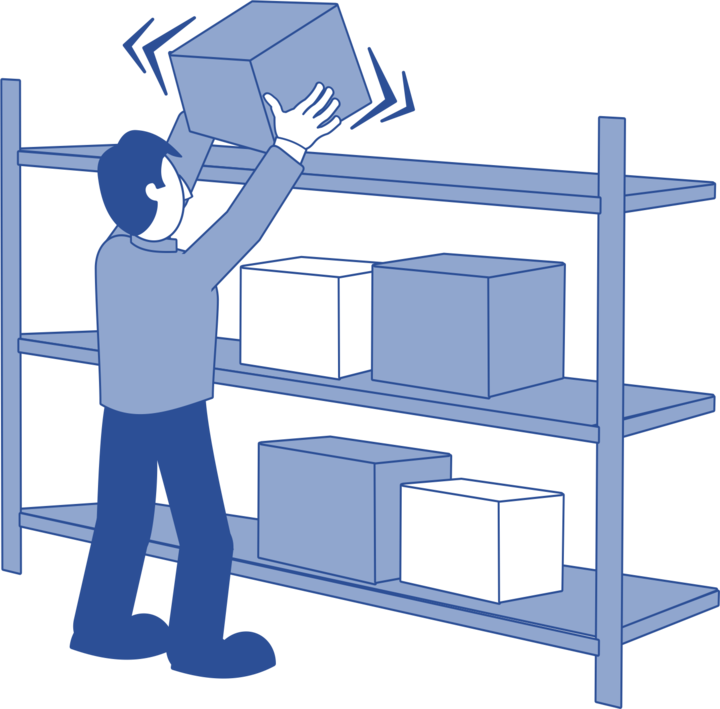

The Manual Handling Operations Regulations 1992 (known as MHOR) are UK laws designed to reduce workplace injuries caused by lifting, carrying, pushing and pulling. They were updated in 2002 and apply to a wide range of tasks, from moving boxes in a warehouse to handling patients in care settings.

Employer duties under MHOR include:

Assessing manual handling risks where there is a chance of injury

Avoiding hazardous handling tasks where possible

Reducing risks if manual handling cannot be avoided

Providing information, instruction, and training to employees

MHOR sits alongside the Health and Safety at Work Act 1974, which sets out broader health and safety duties for both employers and employees in Great Britain. In short: employers must manage risks and provide training, while employees must follow safe systems of work and use equipment correctly.

What does TILE or TILEO stand for in manual handling?

TILE or TILEO are acronyms to help you prepare a manual handling risk assessment. The acronym 'TILE' stands for:

TASK, INDIVIDUAL, LOAD, ENVIRONMENT By considering each of these factors, a suitable risk assessment can be completed. Tileo simply adds OTHER FACTORS to the tile acronym.

What does ICC stand for in manual handling?

This is the Incident Contact Centre (ICC), a 'one-stop' reporting service for work-related health and safety incidents, such as an injury from manual handling that needs reporting under RIDDOR. The ICC is primarily a call centre, open from Monday to Friday on 0345 300 9923.

Can manual handling be avoided completely?

Manual handling can be avoided completely, but it is dependent on the task and situation. Often, it cannot be avoided completely.

Using machines in factory and warehouse work can often completely replace human effort by replacing manual handling tasks with machines, such as forklift trucks, hoists and cranes. However, there will still be occasions when hazardous manual handling cannot be avoided completely, such as delivering heavy parcels, brick-laying, carpet fitting, nursing and many other trades, professions and occupations.

How does good communication reduce the risk of manual handling?

In any manual handling activity where more than one person is involved, good communication is vital to reduce the risk of injury. A nurse trying to move a patient can greatly reduce the risk by communicating to the patient exactly what they are attempting to do and getting the patient to assist as much as possible.

If you are looking for official guidance or a handbook about manual handling, resources are often available from organisations such as the HSE in the UK or your local workplace safety authority. These official handbooks and guidelines provide comprehensive information on safe manual handling practices.

What should a Manual Handling policy at work include?

A manual handling policy at work should include clear procedures for assessing risks, identifying safe methods of lifting or moving loads, training requirements for employees, and guidelines for using equipment and aids. It should also outline the importance of reporting hazards, maintaining good communication among team members, and regularly reviewing safe work practices to ensure ongoing safety and compliance.

What is an ergonomic approach to manual handling?

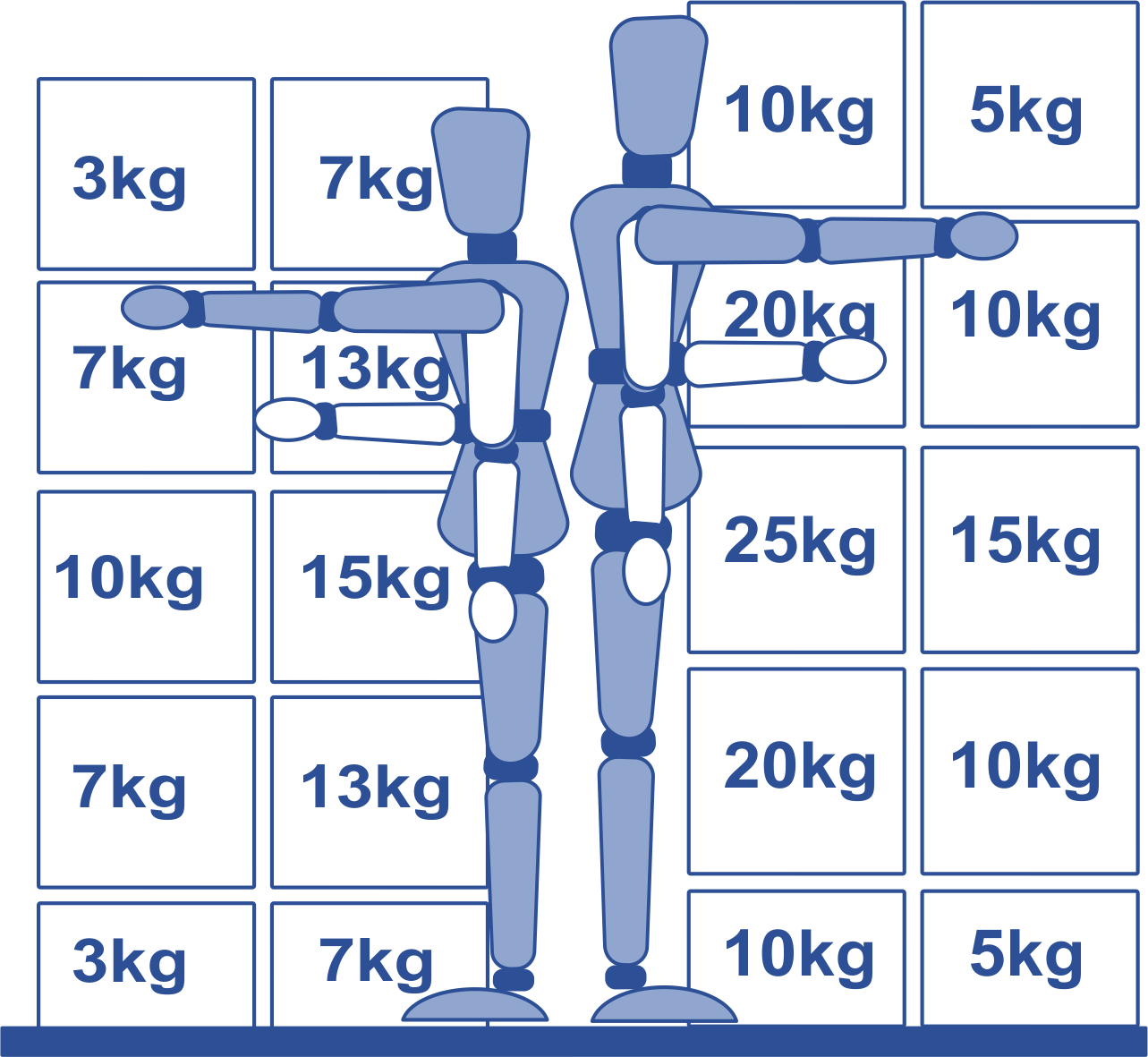

An ergonomic approach to manual handling means reducing risks by adapting tasks, loads and the environment to suit people, rather than forcing people to fit unsafe tasks. This method uses the TILE factors: Task, Individual, Load, Environment.

Task – e.g. duration and frequency

Individual capability – e.g. age & strength

Load – e.g. shape/weight

Environment - altering the working environment to make handling safer.

If you are looking for more information about approaching manual handling ergonomically, consider reading our detailed article: Manual Handling: What does TILE stand for