What are welding fumes?

Welding is a common process used in fabricated metal manufacturing. Welding fumes, including those generated from processes like plasma cutting, are tiny particles that form when the base metal is heated during welding. During the welding process, a piece of metal is heated to a temperature above its melting point, causing parts to evaporate and condense into fumes. These particles can float in the air for a long time.

The type of particles depends on the metal being welded and any coatings on it. For example, welding iron or steel mostly creates iron oxide fumes.

Are welding fumes toxic?

Yes, welding fumes can be harmful. They can cause both short-term and long-term health problems.

Short-term effects:

- Gases like carbon monoxide and nitrogen dioxide can be dangerous, especially in confined spaces

- These gases can irritate the eyes, nose, and throat

- In extreme cases, they can lead to breathing difficulties

Long-term effects:

- Occupational lung disease, including lung cancer

- Occupational asthma

- Other respiratory illnesses

Gases, such as carbon monoxide and nitrogen dioxide, are produced when welding. Exposure to these gases is dangerous, especially in the welder’s breathing zone, as carbon monoxide can cause asphyxiation by affecting the body’s ability to carry oxygen in the blood, and nitrogen dioxide can irritate the eyes, nose, and throat upon contact. These gases are particularly dangerous when working in a confined space, as they can build up quickly and create an oxygen-deficient environment.

The most common long-term health risk associated with exposure to welding fumes is occupational lung disease, including lung cancer, but it can also lead to the development of occupational asthma and other respiratory illnesses.

How can people be protected from inhaling welding fumes?

Health and safety law requires employers to put control measures in place to protect workers from the risks posed by welding fumes.

Here's a simple breakdown of what employers need to do:

- Try to avoid or reduce exposure:

- Can you use a method that makes less fume?

- Is it possible to automate the welding?

- Could you use different materials or processes?

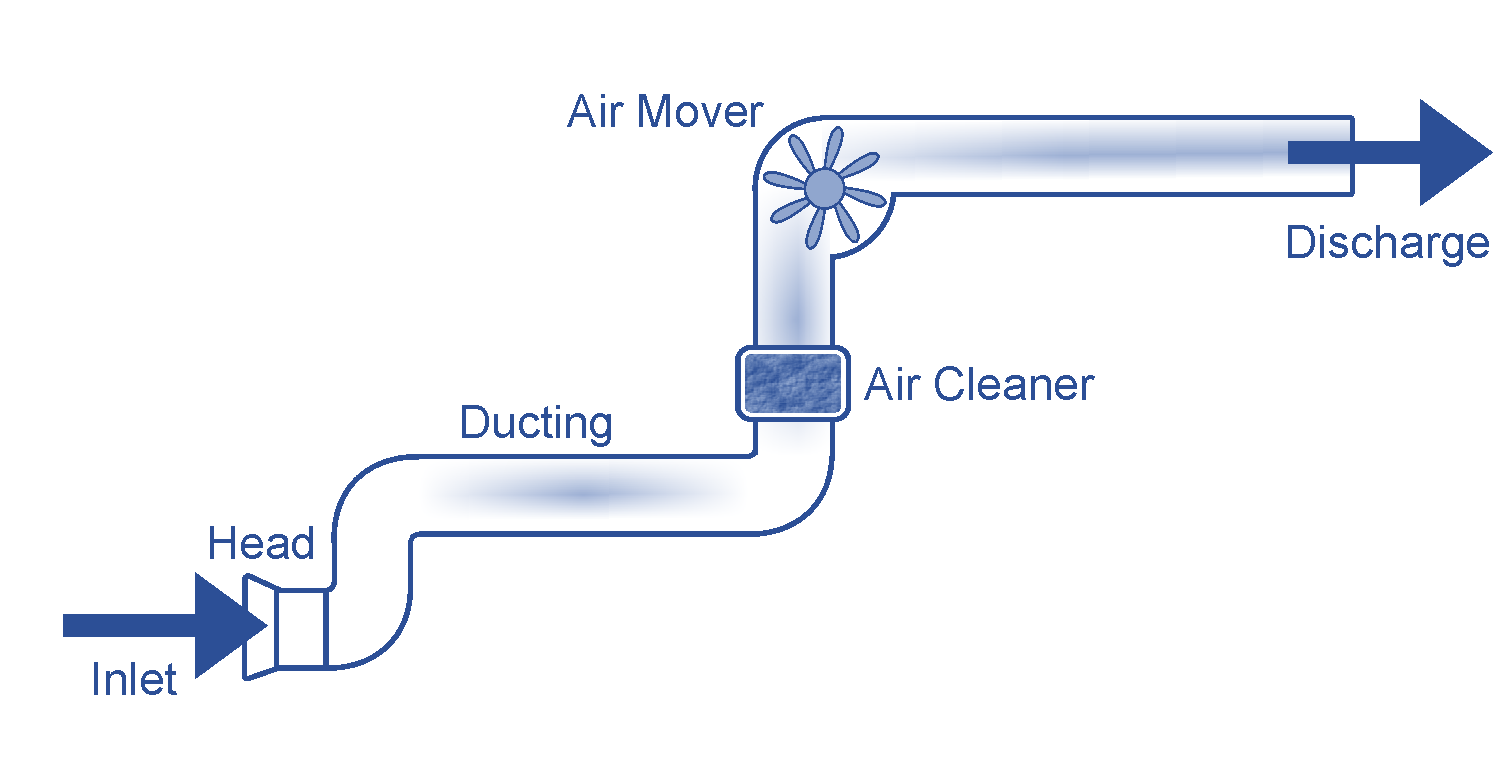

- Use local exhaust ventilation (LEV):

- This is a fume extraction system that removes the fumes

- A fume extractor is much better than a fan, which can spread fumes around

- Provide proper breathing protection:

- Use this when local exhaust ventilation systems are not enough or cannot be used

- Make sure to choose the right type for the job

In situations where fume extraction solutions are not possible, or if there is still a significant risk of worker exposure with a system in place, high quality respiratory protective equipment (RPE) must be provided to prevent inhalation of harmful fumes. Masks should be equipped with a suitable filtration system for effective extraction of particles. Additionally, a portable solution for ventilation may be necessary for some tasks.

The specific kind of equipment used will vary depending on the task and its duration. The Health and Safety Executive has produced Welding Fume Control Guidance that provides more information.

![ventilation system used for COSHH ventilation system used for COSHH]()