Common Uses of Scissor Lifts in Various Industries

Scissor lifts are versatile and valuable in various applications. They increase efficiency and reduce the risk of accidents or injuries when used correctly. Scissor lifts' manoeuvrability and space-saving design make them valuable equipment for many workplaces.

Construction:

In construction, people use these mobile lifts to install lights, set up heating and cooling systems, paint, or build or maintain them at height.

Warehouses:

In warehouses, scissor lifts help pick items, track inventory, and reach shelves.

Automobile:

In the car industry, scissor lifts are a piece of garage equipment handy for fixing cars, vans or motorcycles, changing tyres, and cleaning them up.

Other Industries:

Many other industries use scissor lifts, too, like manufacturing, logistics, and event planning. These lifts provide a safe and steady place to work up high, making work faster and safer for everyone.

Preparing for Scissor Lift Operation

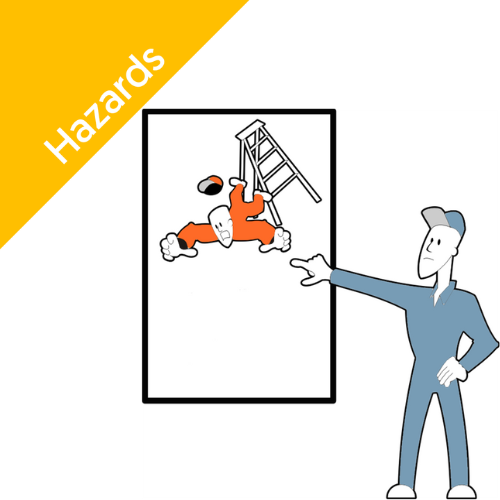

Before operating a scissor lift, it is essential to prepare appropriately to ensure the safety of the operator and those in the work area.

This may include obtaining the necessary training and certifications, such as a powered access licence or PAL card.

Also, it's essential to be familiar with the specific lift model and any safety features or limitations it may have. By preparing, operators can minimise the risk of accidents and ensure a smooth and efficient operation.

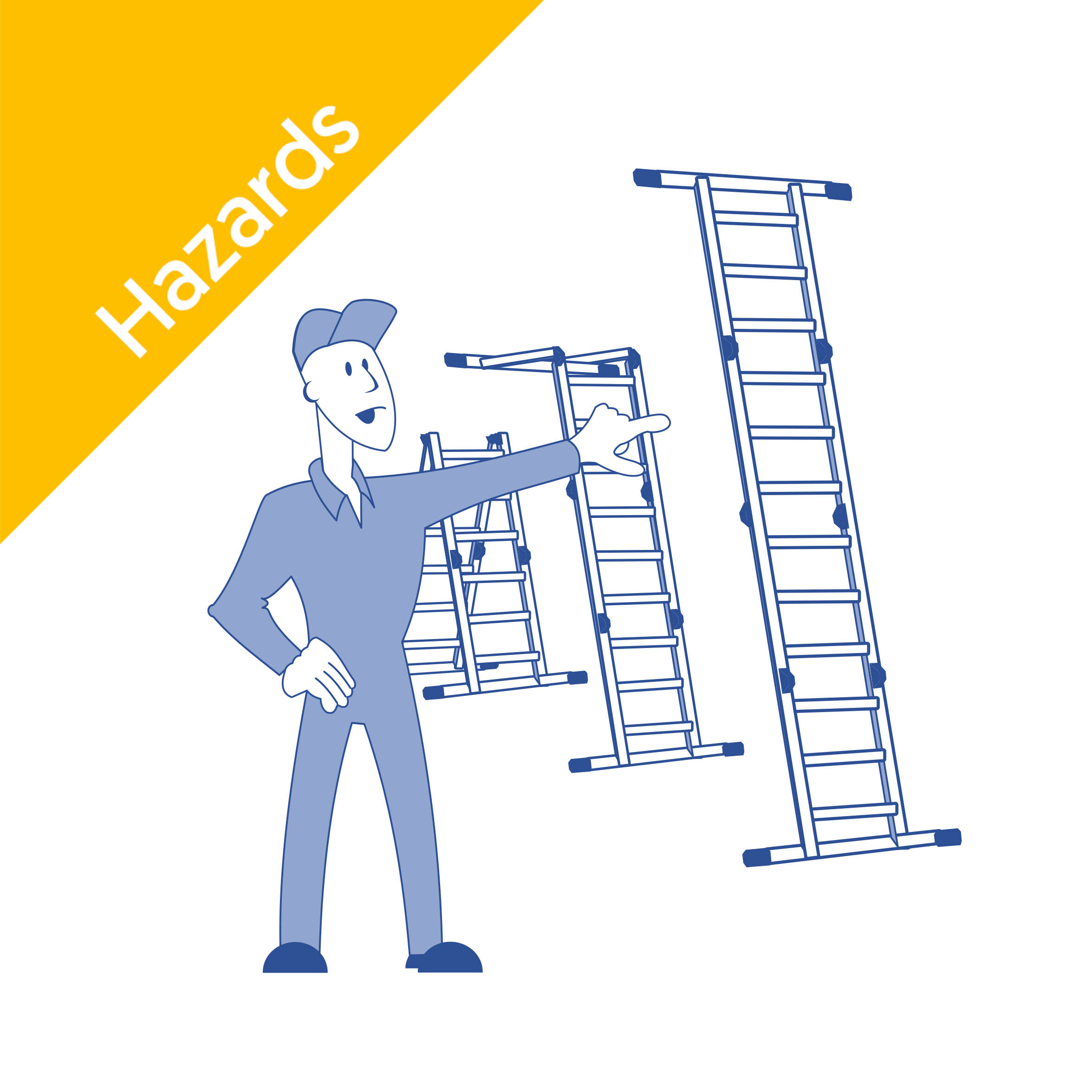

Essential Equipment and Resources Needed

Firstly, it is essential to have access to high-quality, well-maintained lifts. These can be bought, hired or leased.

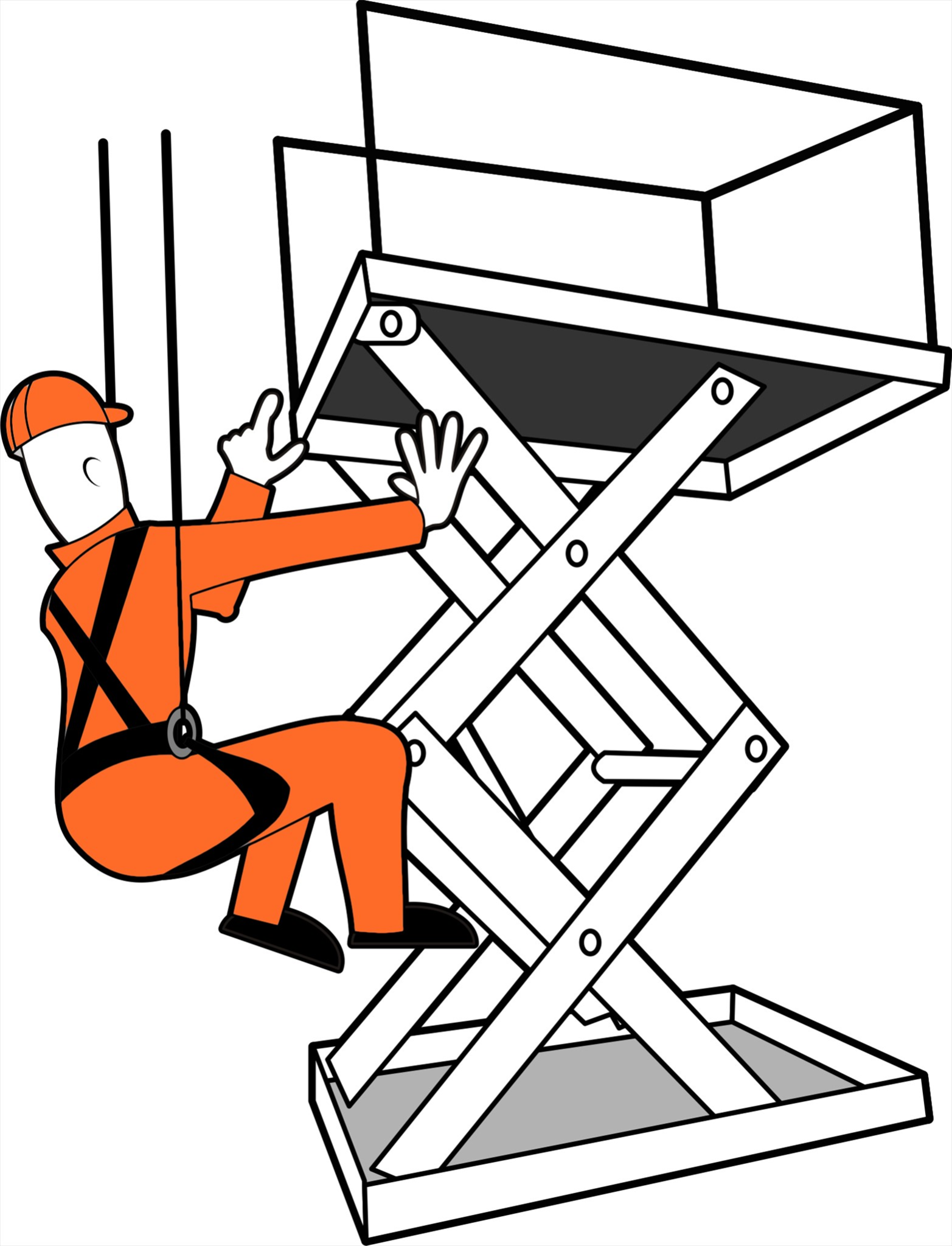

Other essential equipment includes personal protective equipment (PPE), such as hard hats, safety harnesses, and high-visibility vests. Safety signage and barriers may also be necessary to mark off the work area and prevent unauthorised access.

Identifying a Competent Person for Supervision

When operating a scissor lift, it is essential to have a competent person present to supervise the operation.

What is a Competent Person?

A competent person is someone who has proper training and experience to allow them to oversee the safe operation of a scissor lift. This person should be familiar with safety regulations and be able to make decisions about correctly using the equipment. They should also be able to assess external factors such as weather conditions, terrain, and operator experience.

Step-by-Step Guide to Safely Operating a Scissor Lift

Operation requires proper training and adherence to safety guidelines. Here is a step-by-step guide to safely operating a scissor lift:

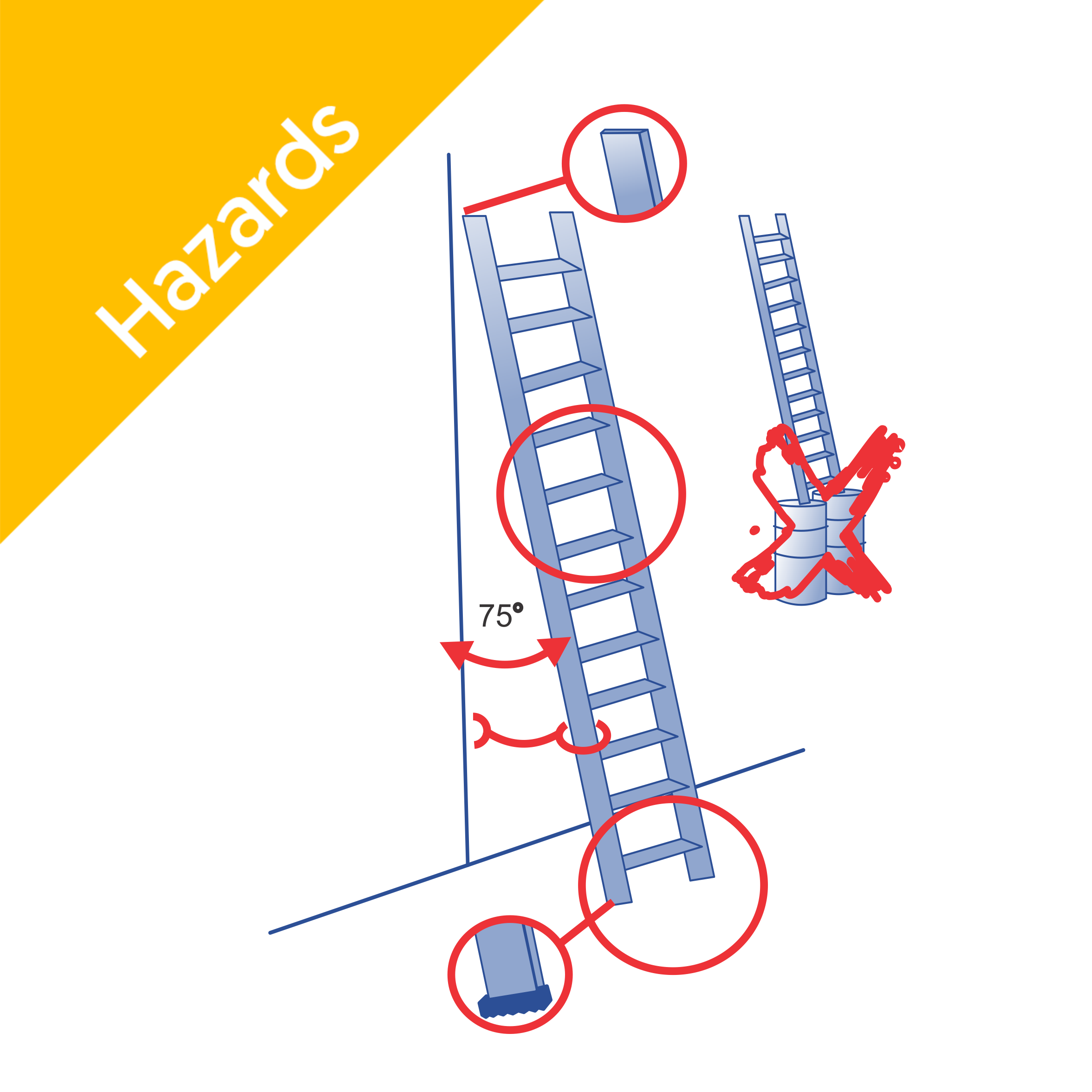

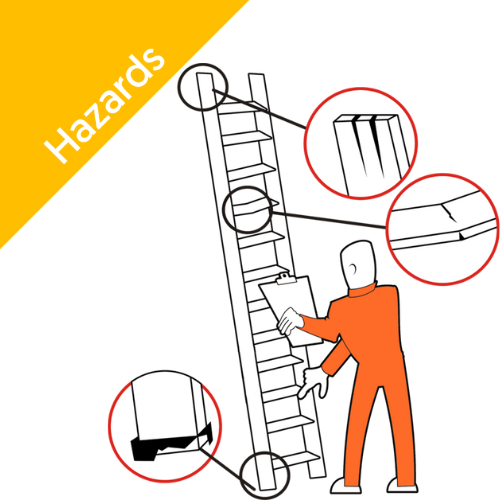

Step 1: Check Before Using

Before using a scissor lift, check that it's in good condition. Look for damage, leaks, or worn parts. Check the controls, emergency stop button, and safety features like guardrails. Also, ensure the battery or fuel levels are good and the lift has been serviced as needed.

Step 2: Position Safely

Make sure the ground is flat and free of hazards like loose objects. If the ground is uneven, adjust the lift's levelling. During work, distribute weight evenly. Don't overload the lift. Stay away from overhead hazards like power lines.

Step 3: Watch Out for Overhead Hazards

Be cautious when working near overhead hazards, such as:

- power lines

- tree branches

- beams

- low ceilings

- doorways and

- other machines and equipment operating in the area.

Plan your work to avoid these hazards and keep a safe distance. Follow safety rules and wear protective gear like hard hats. By being careful, you reduce the risk of accidents.

Step 4: Handle Materials Carefully

Secure materials correctly on the lift's platform and avoid overloading. Follow guidelines for maximum weight capacity. If you need to move materials, use the right equipment to prevent accidents. Be mindful of the lift's stability limits and avoid sudden movements. Handling materials safely ensures a smooth and safe work environment.

Step 5: Exit Safely

Before leaving the platform, secure yourself with safety gear like harnesses. Lower the lift and make sure all controls are off. Use three points of contact when stepping off to stay balanced. Following these steps prevents falls and keeps you safe when leaving the platform.