Working at height does not include:

UK Legislation: Working at Height Regulations

Work at Height Regulations 2005 (WAHR)

These regulations apply to all workplaces and require employers to carry out the following safety measures:

Avoid work at height where possible

Use safety equipment that prevents falls

Minimise the consequences of a fall

Ensure all workers are competent

Plan and supervise all work at height

Inspect equipment regularly and keep records

LOLER Regulations 1998

If you use lifting equipment at height, such as hoists, cranes, MEWPs, goods lifts, or rope systems, the work regulations Lifting Operations and Lifting Equipment 1998 (LOLER) also apply.

LOLER requires:

Planning work safely and supervision of all lifting operations

Thorough examination by a competent person

LOLER inspections and records

Competent operators (usually via LOLER training)

For more information, our Loler Lifting Operations and Loler Risk Assessment guides can help.

The Working at Height Hierarchy of Control

This is central to WAHR compliance and should be applied in order:

1. Avoid work at height

Use long-reach tools, extendable equipment, or redesign tasks to eliminate the need to leave ground level.

2. Prevent falls

If work at height cannot be avoided, use equipment that prevents falls from occurring, such as:

Podium steps

Scaffold towers

Guard rails

Work platforms

MEWPs

3. Mitigate consequences if a fall occurs

Where fall prevention is not possible, use suitable fall protection systems:

Fall restraint systems

Fall arrest systems

Safety nets or airbags

For further information, see our Hierarchy of Control article.

Work at Height Risk Assessments

A compliant working at height risk assessment should include:

Who may be harmed and hoWho may be harmed and how?

Workers, contractors, the public, and people below the work area may sustain personal injury.

Evaluating the height activities and the risks

Fall distance, surface conditions, competency, and equipment condition.

Implementing control measures

Apply the hierarchy of control, choose the safest equipment, and plan rescue arrangements.

Recording findings & reviewing regularly.

This is essential for ongoing compliance.

See our full guide: Working at Height Risk Assessment

Safe Working at Height: Systems, Equipment & PPE

Safe systems of work should include:

Planning and supervising the job

Selecting the right access equipment

Emergency and rescue procedures

Inspection and maintenance

Competence and training requirements

Work at Height PPE

Common work at height PPE includes:

Note: PPE is always the last line of defence.

Ladder Safety Training & Using Ladders Safely

Use of ladders safely requires following HSE’s core rules:

1. Only use ladders for short-duration, low-risk work

They are not appropriate for prolonged tasks.

2. Use the right ladder for the job

There is a wide range of ladders. Choosing the correct ladder for specific work activities supports safe working practices. Extension ladders, step ladders, roof ladders, and mobile ladders all have specific uses.

3. Position, secure and inspect the ladder

1:4 angle for leaning ladders

Firm, level ground

Three points of contact at all times

Regular checks for damage

See our detailed ladder guides:

Safe Ladder Buying Guide

Ladder Safety Laws

Using Roof Ladders Safely

Safety Ladder Training

Common Mistakes to Avoid When Working at Height

Even with the right equipment and planning in place, many accidents occur because of avoidable errors. Some of the most common working at height mistakes include:

1. Using the Wrong Equipment for the Job

Ladders used where a scaffold tower or platform is required are one of the most frequent causes of falls. Equipment should always be selected based on the risk level, duration, and nature of the task.

2. Failing to Secure Ladders or Platforms

Unsecured ladders slipping during use remains a leading cause of injury. Always check stability, ground conditions, and ensure the ladder is properly tied, footed, or stabilised.

3. Not Following the Working at Height Hierarchy of Control

Workers often jump straight to PPE or fall arrest rather than removing hazards or choosing more stable equipment first. Prevention must always come before protection.

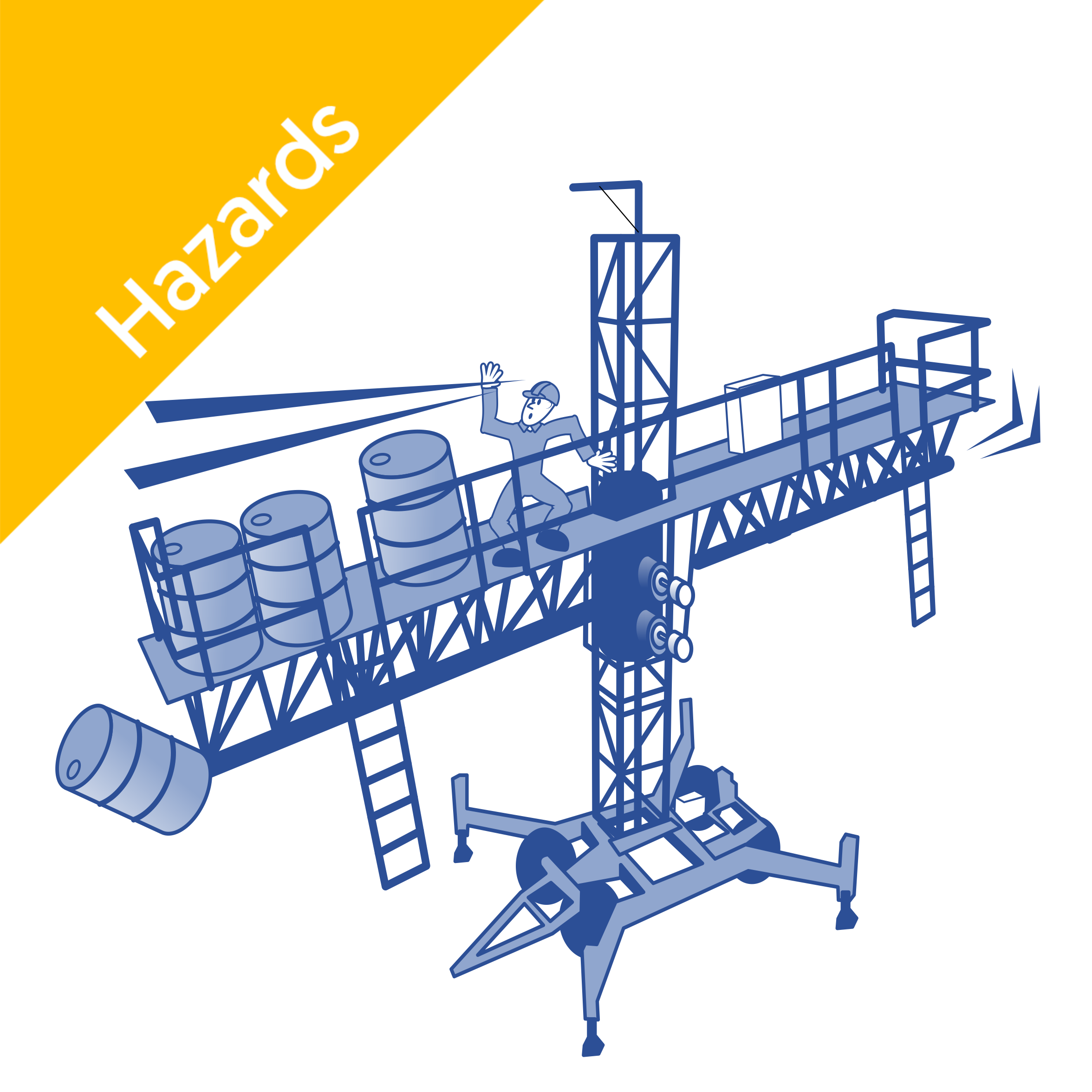

4. Working Without a Proper Risk Assessment

Skipping or rushing a work at height risk assessment can lead to unforeseen hazards such as fragile surfaces, weather exposure, or unsecured materials.

5. Incorrect Use of Fall Arrest or Fall Restraint Systems

Harnesses worn incorrectly, unsuitable anchor points, or damaged lanyards are common issues. Users must always be competent, and equipment must be inspected before use.

6. Lack of Training or Competence

Inadequate working at height training, unfamiliarity with equipment, or assuming workers know what to do can put everyone at risk.

7. Ignoring Weather Conditions

Wind, rain, ice, or poor visibility can make otherwise safe equipment hazardous. Work should be postponed when conditions increase the risk.

8. Overreaching or Leaning

A major cause of ladder-related accidents. Workers should descend and reposition the ladder rather than reaching outside the safe working zone.

Avoiding these mistakes helps ensure compliance with the Work at Height Regulations 2005 and significantly reduces the likelihood of injury.

Fall Protection & Fall Arrest Systems

Fall Protection Systems (Prevention)

Designed to stop a fall from happening:

Guardrails

Work platforms

Scaffold systems

Fall restraint harnesses

Fall Arrest Systems (Mitigation)

Used only when a fall cannot be prevented:

All fall protection systems must be inspected, maintained, and used only by competent workers.

Working at Height Training & Certification

Anyone working at height must receive working at height training appropriate to their role to mitigate the risk of injury. Training covers:

Successful trainees receive a working at height certificate, demonstrating competence.

See also:

Working at Height Certificates

WAH FAQs

LOLER Training & Lifting Equipment Requirements

Workers involved in lifting operations must also receive LOLER training covering:

LOLER regulations

Planning lifting operations

Selecting the right lifting equipment

Thorough examinations

Safe slinging and signalling

Operator competence

This training is essential for anyone using or supervising MEWPs, hoists, cranes, lifting accessories, or rope systems.

To understand LOLER health and safety in more detail, our LOLER Lifting Operations FAQ can help.

Where to Find Official Guidance on Working at Height in the UK

For the most up-to-date information on legal requirements, safety standards, and best practices, the following official sources provide authoritative guidance:

1. Health and Safety Executive (HSE) – Working at Height Guidance

The HSE publishes the definitive guidance on complying with the Work at Height Regulations 2005, including planning, equipment selection, ladder use, and risk assessments.

This includes:

2. HSE Safety Bulletins and Sector-Specific Advice

HSE regularly publishes alerts, case studies, and enforcement notices related to work at height, which can highlight real-world risks and lessons learned.

3. Government Legislation Website

The full legal text of the Work at Height Regulations 2005 is available on the official UK legislation website.

4. For LOLER Guidance

For lifting equipment used at height, consult:

These documents explain responsibilities for planning lifting operations, inspections, competence, and safe systems of work.

You can refer to these resources whenever you need authoritative, up-to-date guidance or clarification on your legal duties.

Conclusion: Taking Control of Working at Height Safety

Working at height does not have to be dangerous. With the right planning, training and equipment, most falls are entirely preventable.

To comply with the Working at Height Regulations 2005 and, where required, LOLER regulations, ensure that:

All work is properly planned and supervised

Equipment is inspected and fit for purpose

Competent workers carry out the task

A suitable work at height risk assessment is in place

Workers receive accredited working at height training

Fall protection systems are used correctly

Rescue arrangements are in place before work begins

Working at Height Certificate

Equip yourself and your workforce with the essential skills to work safely at height.

Complete our accredited online training to gain your Working at Height Certificate fast, compliant, and fully online.