Health Risks of Vibration Exposure

The Health and Safety Executive (HSE) estimates that over two million UK workers are at risk of developing serious conditions due to excessive daily vibration exposure. These conditions include:

HAVS, which damages nerves and blood circulation.

Vibration White Finger, a symptom of HAVS that causes blanching of the fingers.

Carpal Tunnel Syndrome, is caused by nerve compression in the wrist.

Whole Body Vibration (WBV), which can lead to chronic back pain.

Why Accurate Vibration Measurement Matters

Employers must measure the level of vibration workers are exposed to to determine risk and ensure compliance with legal exposure limits. A well-structured vibration risk assessment helps:

Identify and control exposure risks.

Prevent long-term health effects.

Comply with codes of practice and good practice standards.

Making employees aware of the risk of vibration should be a priority. Try our short online course. We offer discounts on bulk orders of our courses so organisations can train more workers for less of the training budget.

HAV Assessment: Measuring Vibration

A thorough vibration risk assessment requires measuring both:

Vibration magnitude: The amount of vibration exposure, measured in m/s², which represents how rapidly a tool or machine moves back and forth.

Daily exposure time: The total duration a worker operates vibrating equipment per day.

Understanding Legal Vibration Exposure Limits

Legal exposure limits, including the Exposure Limit Value (ELV) and Exposure Action Value (EAV), are established to protect workers from the damaging effects of vibration. The ELV represents the maximum allowable exposure to vibration in a single working day, while the EAV is the level of exposure at which action must be taken to reduce or eliminate the risk.

These limits vary depending on the type of vibration (e.g., hand-arm or whole-body vibration) and are subject to periodic review to ensure they remain in line with the latest health and safety research.

Employers must implement data acquisition methods to track vibration measurement results accurately and apply effective controls when necessary.

How Do You Measure Vibration Exposure in the Workplace?

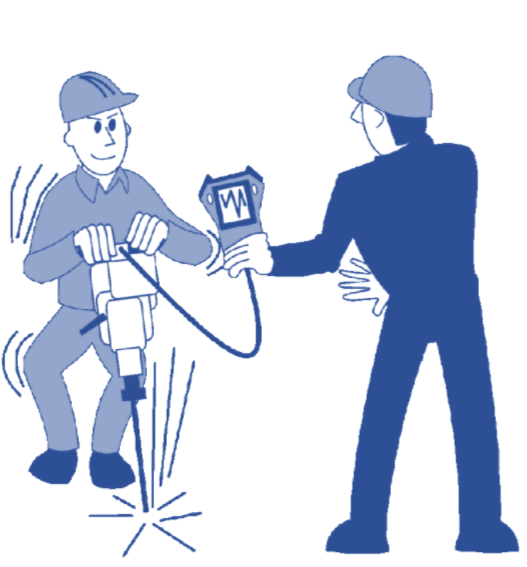

To measure vibration exposure, employers must assess both the magnitude of vibration and the duration of exposure. Tools like vibration meters and ready reckoners can help estimate levels, but direct measurement ensures accuracy, especially with tools and machinery that show varying levels of vibration.

Ready reckoners help assess and manage the risk of vibration exposure. It helps employers determine if exposure levels are within safe limits. While ready reckoners and manufacturer data can provide an estimated amount of vibration exposure, these do not account for factors like:

Tool age and maintenance.

Work conditions (e.g., foundries, fettling, drilling, or machinery use).

Operator technique.

To get precise readings, direct vibration measurement using accelerometers vibration meters and piezoelectric sensors is recommended. These instruments detect the amplitude, velocity, and frequency of vibrations.

Accelerometers, for example, can be mounted directly to machinery or hand tools to measure vibration intensity. These devices offer a high level of precision and are often used in real-time measurements to monitor daily exposure. However, it is important to ensure that the tool is calibrated properly to avoid inaccurate readings that could compromise worker safety

Best Practices for Vibration Control

Use the HSE’s online HAV calculator to assess exposure.

Obtain vibration measurement data for each tool used.

Follow codes of practice by monitoring daily exposure and ensuring it stays within the first exposure limit.

Implement control measures during the transitional period for workers already exposed to high levels of vibration.

Provide regular health surveillance for employees exceeding the daily exposure limit value.

Final Thoughts

Accurate vibration measurement is vital to protecting workers and complying with legal exposure limits. Employers must proactively assess daily vibration exposure, track HAVS exposure limits, and apply good practice strategies to reduce risk.

To learn more about these requirements and stay compliant with the Control of Vibration at Work Regulations, consider our Vibration Awareness Training Course. This course provides essential knowledge on managing vibration risks, including practical tools for vibration measurement, personal protection equipment, and risk assessment.