History and Background of Manual Handling Legislation

The Manual Handling Operations Regulations 1992 were created to bring UK law in line with the EEC Directive 90/269/EEC on the manual handling of loads. This directive set minimum health and safety requirements across Europe.

In Great Britain, the regulations were introduced as Statutory Instrument 1992/2793 and later updated by the Health and Safety (Miscellaneous Amendments) Regulations 2002. These changes are sometimes referred to as MHOR 1992 revised 2002.

The regulations are closely linked to the Health and Safety at Work etc. Act 1974 (often called the Work Act), which sets the general framework for workplace safety.

In Northern Ireland, a separate but very similar set of regulations applies under Northern Ireland legislation.

What Are the Manual Handling Operations Regulations?

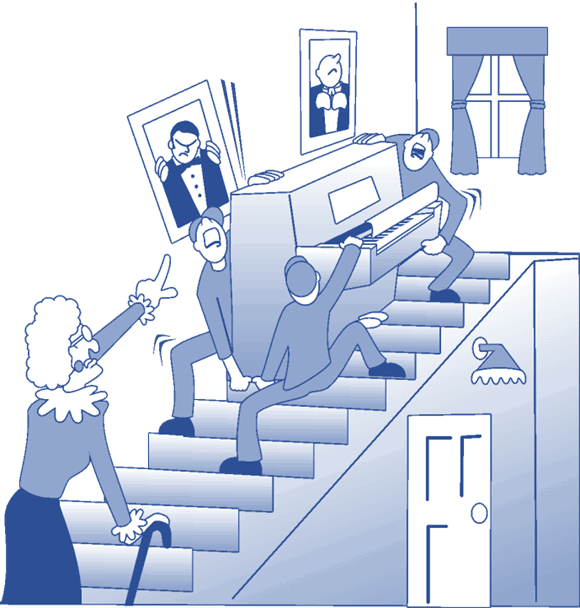

The Manual Handling Operations Regulations 1992 (MHOR) are UK work regulations designed to reduce injuries caused by lifting, carrying, pushing, or pulling loads. They require employers to avoid hazardous manual handling, carry out risk assessments, and take appropriate steps to protect workers from musculoskeletal injuries.

A load is defined as any discrete movable object. This can include boxes, equipment, animals, or even people. (Tools or machinery are not considered a load when being used for their normal function.)

A manual handling operation means any activity involving transporting, supporting of a load, lifting, lowering, pushing, pulling, carrying, throwing, or even deliberately dropping an object.

An injury includes any harm caused by manual handling, especially musculoskeletal injuries such as back strain. Injuries from sharp edges, heat, or slippery surfaces of a load are included.

Breakdown of Key Regulations

Regulation 2 – Definitions

Defines what counts as manual handling, what a load is, and what types of injuries are covered.

Regulation 4(1) – Employer Responsibilities

Employers must:

Avoid hazardous manual handling where possible (for example, by using machinery instead of human effort).

If unavoidable, carry out a suitable and sufficient manual handling risk assessment.

Consider the task, individual, load, and environment (see [internal link placeholder] TILE/TILEO/LITE article).

Take appropriate steps to reduce risks, using practical and effective measures.

Provide precise information and general indications about loads, such as weight and the heaviest side.

The HSE provides manual handling assessment charts (MAC tool) to help employers judge risks.

Regulation 4(2) – Review of Assessments

Employers must keep risk assessments up to date and review them after any major change, accident, or if results of any health surveillance show problems.

Regulation 4(3) – Factors Before Lifting

Employers must consider:

The physical suitability of the employee.

Clothing, footwear, or other personal effects.

The employee’s knowledge and training.

The results of any relevant health surveillance.

Whether the worker belongs to an at-risk group.

Regulation 5 – Employee Responsibilities

Employees also have a legal duty to:

How Should Manual Handling Risk Assessments Be Carried Out Under the Regulations?

Under the Manual Handling Operations Regulations 1992, employers have a legal duty to carry out a suitable and sufficient risk assessment whenever hazardous manual handling cannot be avoided. The goal is to reduce risks of musculoskeletal injuries from the manual handling of loads.

A good manual handling risk assessment should include:

Task – Look at what the job involves: lifting, lowering, pushing, pulling, or supporting of a load. Consider repetition, twisting, reaching, or working below knee/above shoulder height.

Individual – Assess the worker’s physical capabilities, training, clothing, footwear, and whether they belong to an at-risk group.

Load – Record the size, shape, stability, and weight of the load. Provide workers with precise information or general indications of the weight and the heaviest side where relevant.

Environment – Check for space constraints, uneven floors, poor lighting, temperature, or other environmental hazards.

Other Factors – Use mechanical aids where possible, and take into account the results of any health surveillance, time pressures, and team handling issues.

Employers should take appropriate steps to reduce the risks identified. This may include redesigning the task, using lifting aids, adjusting workplace layout, or providing training in safe techniques.

Risk assessments must be:

Kept up to date, especially after accidents or changes in the task.

Recorded in writing if five or more employees are in the organisation.

Reviewed regularly as part of wider management of health and safety at work regulations.

What Changes Have Been Made Since 1992?

The Manual Handling Operations Regulations 1992 were revised in 2002 by the Health and Safety (Miscellaneous Amendments) Regulations.

Key changes included:

Updates to remove outdated references and align MHOR with wider management of health and safety at work regulations.

Clarifications of employer duties for providing precise information and general indications about loads.

Revisions in line with other subsequent legislation and statutory instruments.

When checking the text of the legislation online, you will see notes on known changes and known outstanding effects that show how the regulations stand today.

Who Enforces Manual Handling Regulations?

In Great Britain, the Health and Safety Executive (HSE) enforces MHOR.

Local authorities may also have enforcement duties depending on the type of workplace.

In Northern Ireland, enforcement is carried out by HSENI (Health and Safety Executive for Northern Ireland).

Professional bodies such as IOSH (Institution of Occupational Safety and Health) provide training, guidance, and policy support.

Where Can I Find the Full Text of the Regulations?

The full text of the legislation can be read on the official legislation.gov.uk website. This includes:

The original 1992 regulations.

Updates made by later statutory instruments (like the 2002 amendments).

Editorial notes, appendices, known changes, and outstanding effects.

This source is updated by the editorial team to show the law as it applies at the current time.

What Penalties Can Employers Face for Non-Compliance?

Failure to comply with manual handling legislation 1992 can have serious consequences.

The HSE can issue improvement or prohibition notices.

Employers may face fines or prosecution under the Health and Safety at Work etc. Act 1974.

Workers injured due to incorrect manual handling may bring civil claims against the employer.

Breaches of manual handling legislation UK also damage an organisation’s reputation and can lead to higher costs due to lost time and compensation.

Summary & Key Takeaways

The Manual Handling Operations Regulations 1992 (as amended in 2002) are the main rules for preventing musculoskeletal injuries in the workplace.

Employers must avoid hazardous manual handling where possible, do risk assessments, provide training, and give workers precise information about loads.

Employees also have a legal duty to take care of themselves and cooperate.

Compliance protects health, reduces accidents, and helps organisations meet their responsibilities under the law.

Frequently Asked Questions

What is MHOR 1992 revised 2002?

It is the updated version of the original 1992 regulations, amended by later statutory instruments in 2002.

Which of these do MHOR define as loads?

A load means any discrete movable object, including people or animals. Tools and machinery are not loads when used for their intended purpose.

Why were the Manual Handling Operations Regulations introduced?

They were introduced to reduce injuries caused by hazardous manual handling, in line with European (EEC) requirements, and to protect workers’ health.

Is manual handling legislation the same in Northern Ireland?

Northern Ireland has its own set of regulations under Northern Ireland legislation, but they are almost identical to those in Great Britain.