When Should Team Lifting Be Used?

Not every load requires a team lift, but certain warning signs indicate when it’s the best option. Use team lifting when:

The load is too heavy for one person.

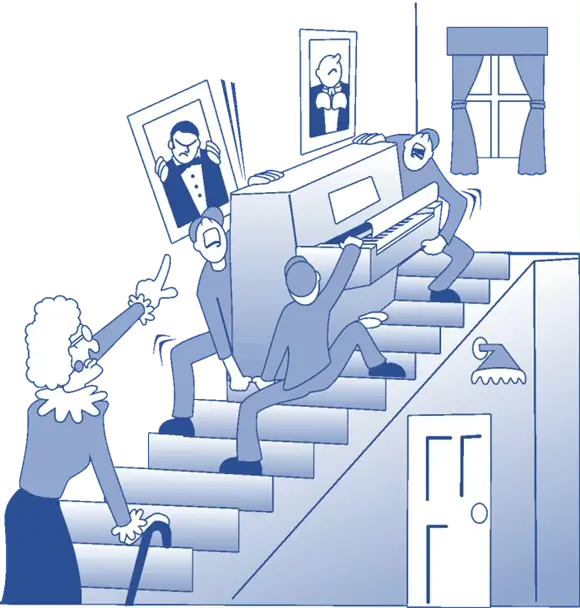

You must twist, reach, or bend awkwardly.

The load needs to be lifted above shoulder height or from below knee level.

The carrying distance is long, or the pathway is uneven.

The environment makes solo lifting unsafe (tight spaces, poor lighting, etc.).

Whenever possible, use mechanical aids (like hoists or pallet trucks) instead. Team lifting should be a control measure, not the first choice. To understand when team lifting is appropriate and how it fits alongside risk assessments, TILEO, and mechanical aids, see our complete manual handling overview.

How TILEO Helps in a Team Lift

Before any manual handling activity, employers must assess the risk using the TILEO framework:

Factor | Questions to Ask |

|---|

Task | Does the task involve twisting, reaching, or long distances? |

Individual | Are team members of similar height, strength, and ability? |

Load | Is it heavy, large, unstable, or difficult to grip? |

Environment | Is there enough space, good lighting, and a clear path? |

If the risk is high in any of these areas, a team lift or mechanical aid should be used to reduce the chance of injury.

How to Prepare for a Team Lift

Good preparation makes all the difference. Before starting:

Assess the load – Check its weight, balance, and grip points.

Select suitable team members – Aim for similar height and strength.

Plan the route – Clear obstacles and check doorways and floor surfaces.

Appoint a team leader – One person should give clear lifting commands.

The team leader should call out instructions like “Ready… lift on three” to keep everyone in sync.

Safe Team Lifting Techniques

When performing the lift:

Stand close to the load with feet shoulder-width apart.

Bend your knees, not your back.

Keep the load close to your body.

Lift smoothly, using your legs and core muscles.

Move your feet instead of twisting your torso.

Communicate clearly — lift, move, and lower together.

If anyone feels strain or the load becomes unstable, stop immediately and re-assess.

What Type of Equipment Can Make Team Lifting Safer?

Even when working as a team, using the right manual handling equipment can make lifting tasks much safer and easier. These aids reduce the amount of physical effort needed, helping to prevent strain and lower the risk of musculoskeletal injuries.

The choice of equipment depends on the task, load type, and environment, but common tools include:

Trolleys and platform trucks – Ideal for moving heavy boxes or containers over flat ground.

Pallet trucks – Useful in warehouses and storerooms for shifting palletised goods with minimal lifting.

Hoists and cranes – Best for lifting very heavy or awkward loads that would otherwise require multiple people.

Lift tables and height-adjustable platforms – Allow you to raise or lower items to a safe working height, reducing bending and stretching.

Slings and lifting straps – Help distribute weight more evenly across the body and provide better grip on large or uneven items.

Conveyor systems – Reduce the need to carry loads manually over distances, especially in production or packing areas.

Even when using equipment, workers should still follow safe manual handling techniques and communicate clearly as a team. The equipment is there to assist, not replace good lifting practices.

Employers should also include the use of handling aids in their manual handling risk assessments and ensure that all staff are trained in how to use the equipment correctly.

Team Lifting or Equipment Checklist

Situation | Best Approach | Why |

|---|

The load is too heavy for one person but evenly shaped and easy to grip | Team Lift | Sharing the weight between workers keeps strain low and improves control. |

The load is bulky, unstable, or has an awkward shape | Mechanical Aid (e.g., hoist or trolley) | Equipment provides better balance and reduces risk of sudden shifting. |

The load needs to be moved across a long distance | Use a Trolley or Pallet Truck | Reduces fatigue and avoids carrying for extended periods. |

The lift involves heights (above shoulder or below knee) | Use Height-Adjustable Equipment | Keeps handling within the safe lifting zone. |

There’s limited space or uneven flooring | Reassess Task / Use Equipment | Poor footing makes manual handling unsafe, even with a team. |

The team members vary in strength or height | Use Equipment Instead of Team Lift | Prevents uneven load sharing and potential strain injuries. |

The task is repetitive throughout the day | Use Handling Aids or Rotate Tasks | Minimises long-term musculoskeletal strain. |

Legal Duties for Employers and Employees

Under the Manual Handling Operations Regulations (MHOR) 1992, employers must:

Avoid hazardous manual handling where possible.

Assess any manual handling that cannot be avoided.

Reduce the risk of injury through safe systems of work, including team lifting.

Employees also have a duty to follow safe procedures and attend any required manual handling training provided by their employer.

Conclusion

A well-planned and coordinated team lift helps prevent injuries and ensures compliance with UK manual handling regulations. Always assess the risks, plan ahead, and communicate clearly with your team. When in doubt, stop and re-evaluate; safety should always come first.

If you’d like support with manual handling assessments or training, consider arranging a short consultation with one of our safety specialists.

Frequently Asked Questions

1. What is key during a team lift?

Clear communication and coordination are the most important factors. One person should lead, giving clear commands like “lift on three” so everyone moves at the same time.

2. When should team lifting be used instead of solo lifting?

Use a team lift when a risk assessment shows that the load is too heavy, large, or unstable for one person to manage safely. If mechanical aids are available, they should always be considered first.

3. What are common mistakes to avoid during a team lift?

Avoid lifting without planning, twisting while carrying, using uneven team sizes, or failing to communicate. Never assume everyone knows the plan; always discuss it first.

4. Do employers have to provide training on team lifting?

Yes. Under MHOR 1992, employers must ensure all staff receive manual handling training, including safe lifting techniques and when to use team handling.