Manual Handling in the Construction Industry

Manual handling refers to any activity involving the transportation or support of a load by hand or bodily force. This includes lifting, lowering, carrying, pushing, or pulling. On a construction site, that could mean moving bags of cement, installing plasterboard, or shifting heavy tools and equipment.

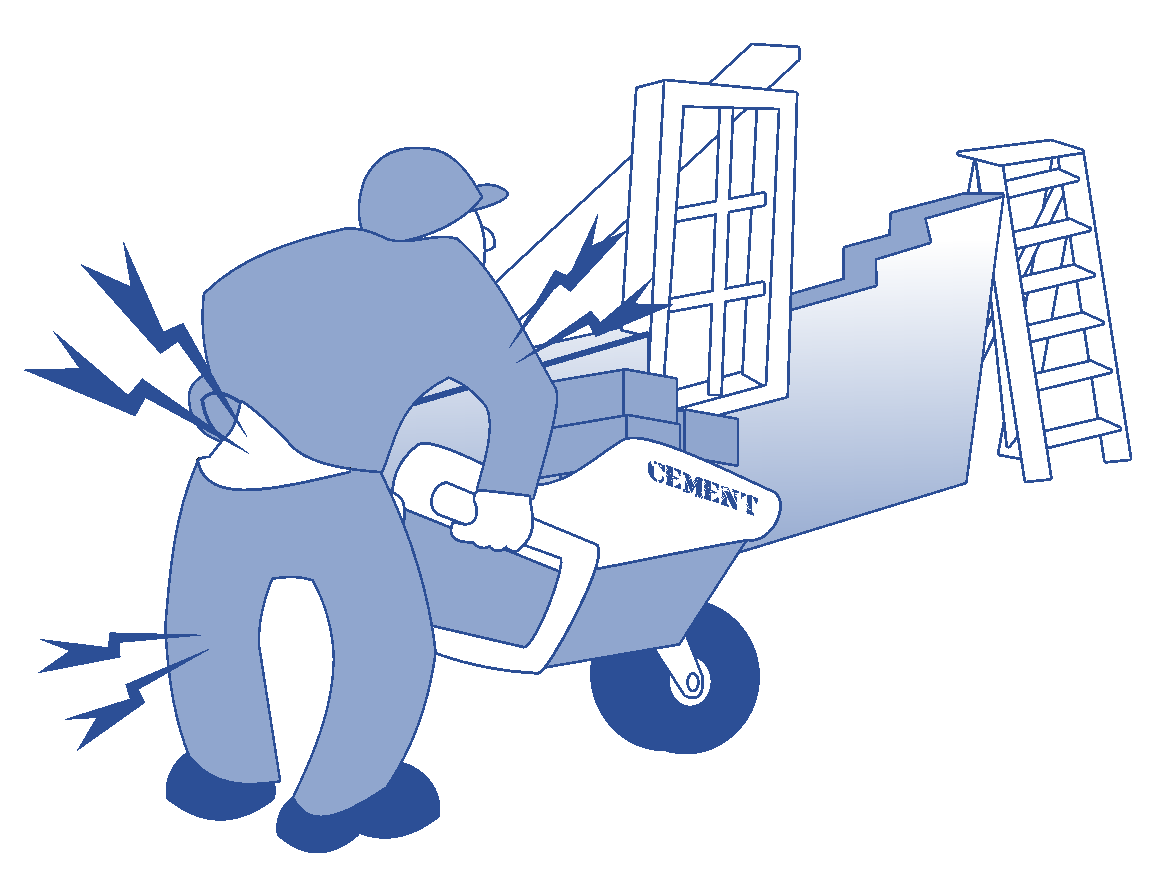

The combination of heavy loads, uneven ground, and awkward postures makes construction a particularly high-risk environment. Understanding where those risks originate is the first step in preventing injury.

What are some common Manual Handling Tasks on Site?

Construction workers face a wide range of manual handling activities each day, including:

Carrying bricks, timber, or bags of cement

Pushing wheelbarrows or trolleys across rough terrain

Lowering tools or materials into trenches

Installing panels, windows, or plasterboard

Even tasks that seem minor can build up strain over time. When performed repeatedly, poor posture or technique can lead to chronic back and shoulder pain.

Manual Handling Risks and Hazards

Unsafe lifting techniques and poor working conditions are the main causes of injury. These include:

Twisting or bending the back while lifting

Holding loads away from the body

Working in cramped or awkward positions

Rushing tasks or skipping proper lifting form

Common Injuries

MSDs develop gradually and can severely limit movement and strength. They’re one of the top reasons for lost working days in construction. These injuries are preventable with the right approach.

How to Assess Manual Handling Risks on Construction Sites

Every site is different, and that’s why a manual handling risk assessment is essential. The TILE method is a simple way to structure your assessment:

Factor | Questions to Ask |

|---|

Task | Does it involve twisting, reaching, or repetitive lifting? |

Individual | Is the worker trained, fit, and free from injury? |

Load | Is it heavy, awkward, or hard to grip? |

Environment | Is there enough space, good lighting, and stable footing? |

By breaking down each task this way, you can identify where the greatest risks lie and decide on appropriate control measures.

See our Knowledge Bank to learn more information about TILE, LITE and TILEO risk assessment methods for manual handling.

Control Measures: Reducing the Risks

The safest way to handle manual tasks is to avoid them where possible. If that’s not feasible, reduce the risk using these practical measures:

1. Use Mechanical Aids

Whenever possible, take the strain off your body with:

Pallet trucks and sack barrows

Hoists, conveyors, and cranes

Telehandlers and forklifts

Specialist grips and lifting attachments

2. Improve Site Layout

Good planning can remove many hazards before work begins. For example:

Deliver materials directly to the point of use

Store heavy items at waist height

Keep walkways clear and well-lit

Avoid carrying materials over long distances

3. Use Lighter or Pre-Assembled Materials

Choose products that reduce the physical effort required, such as:

Lightweight trench blocks with handholds

Pre-mixed mortar or concrete is pumped into place

Modular systems that reduce repetitive lifting

4. Encourage Safe Work Practices

Even with the right tools, poor technique still causes injuries. Always:

Keep the load close to your body

Bend your knees, not your back

Avoid twisting. Turn with your feet instead

Work at a steady pace and take breaks

Legal Responsibilities in Construction

Under the Manual Handling Operations Regulations 1992, employers must:

Avoid hazardous manual handling where possible.

Assess tasks that can’t be avoided.

Reduce the risk of injury as far as reasonably practicable.

That means providing proper training, suitable lifting aids, and safe work systems. Supervisors also have a duty to monitor and review controls to make sure they’re working effectively.

For workers, the law requires cooperation. This includes following training, using equipment safely, and reporting any hazards or injuries.

Creating a Safer Construction Culture

Reducing manual handling injuries can be helped by creating an on-site safety culture. A proactive approach includes:

Regular manual handling training tailored to the tasks workers perform

Toolbox talks on lifting and site safety

Clear communication about risk assessments and safe procedures

Encouraging feedback from workers about manual handling challenges

When everyone on site understands the risks and feels responsible for managing them, safety improves naturally.

Conclusion

Manual handling will always be part of construction work, but injuries don’t have to be. By assessing risks, using mechanical aids, planning site layouts, and maintaining safe lifting habits, you can dramatically reduce the chance of injury.

A safe site is a productive site. With the right training and awareness, every worker can help make manual handling safer for themselves and their team.

Frequently Asked Questions

What are the most common manual handling injuries in construction?

Back injuries and musculoskeletal disorders are the most common manual handling injuries in construction. These often result from lifting heavy or awkward loads. Workers also frequently experience muscle strains, sprains, and shoulder or neck pain caused by poor technique or repetitive movement.

What is the legal guidance for manual handling in construction?

The Manual Handling Operations Regulations 1992 require employers to avoid or reduce manual handling risks. The Health and Safety Executive (HSE) enforces these rules and provides detailed guidance for construction environments.

What control measures reduce manual handling risks on site?

Key controls include using lifting aids, improving site layout, breaking down heavy loads, and rotating tasks to avoid fatigue. Good planning can eliminate many risks before work begins.

Do construction workers need manual handling training?

Yes. Manual handling training is essential to teach safe lifting techniques and raise awareness of site-specific hazards. Refresher sessions help reinforce good habits.

How can employers prevent long-term health issues like MSDs?

Encourage safe practices, provide ergonomic equipment, rotate tasks, and make sure workers take regular breaks. Early reporting of pain or discomfort helps prevent long-term damage.