Make sure your path is clear and well-lit before you begin.

3. Check Your Own Capability

Everyone’s abilities differ, and they can vary day to day. Consider:

Am I trained to handle this type of load?

Am I physically able to do it safely today?

Do I feel rushed or fatigued?

Do I need help from a colleague?

Never ignore discomfort, dizziness, or pain.

4. Check Whether There’s a Safer Alternative

Before lifting manually, ask:

Can the task be automated or mechanised?

Would a trolley, pallet truck, hoist, or slide sheet reduce the risk?

Can the load be divided into smaller parts?

If there’s a safer option, use it.

5. Check for Required PPE or Information

Depending on the load or environment, you may need:

Make sure you have everything before starting.

6. Check Your Route and Final Position

Finally, plan the whole lift before you begin:

This final check prevents awkward adjustments mid-lift, which is when injuries commonly happen.

Why These Checks Matter

These simple assessments form the basis of a safe manual handling approach. They help you identify hazards early and prevent the kind of sudden, unexpected strain that leads to injury. They also align with the TILEO method (Task, Individual, Load, Environment, Other Factors) and support your legal duties under MHOR.

Read our guide to avoiding the most common manual handling injuries in our Knowledge Bank.

Manual Handling Risks in Different Industries

Risks vary widely depending on the sector:

Industry | Examples of Common Manual Handling Hazards |

|---|

Healthcare | Moving patients, supporting mobility, pushing equipment |

Construction | Handling building materials, loading/unloading deliveries |

Warehousing | Repetitive box lifting, order picking, pallet handling |

Office | Moving office furniture, carrying supplies |

For step-by-step guidance, see our full Manual Handling Risk Assessment Guide.

Key Principles of Safe Manual Handling (HSE Guidelines)

The HSE sets out three core principles:

Avoid hazardous manual handling where possible

Assess unavoidable tasks

Reduce risk through controls such as personal protective equipment, training, and safe systems of work

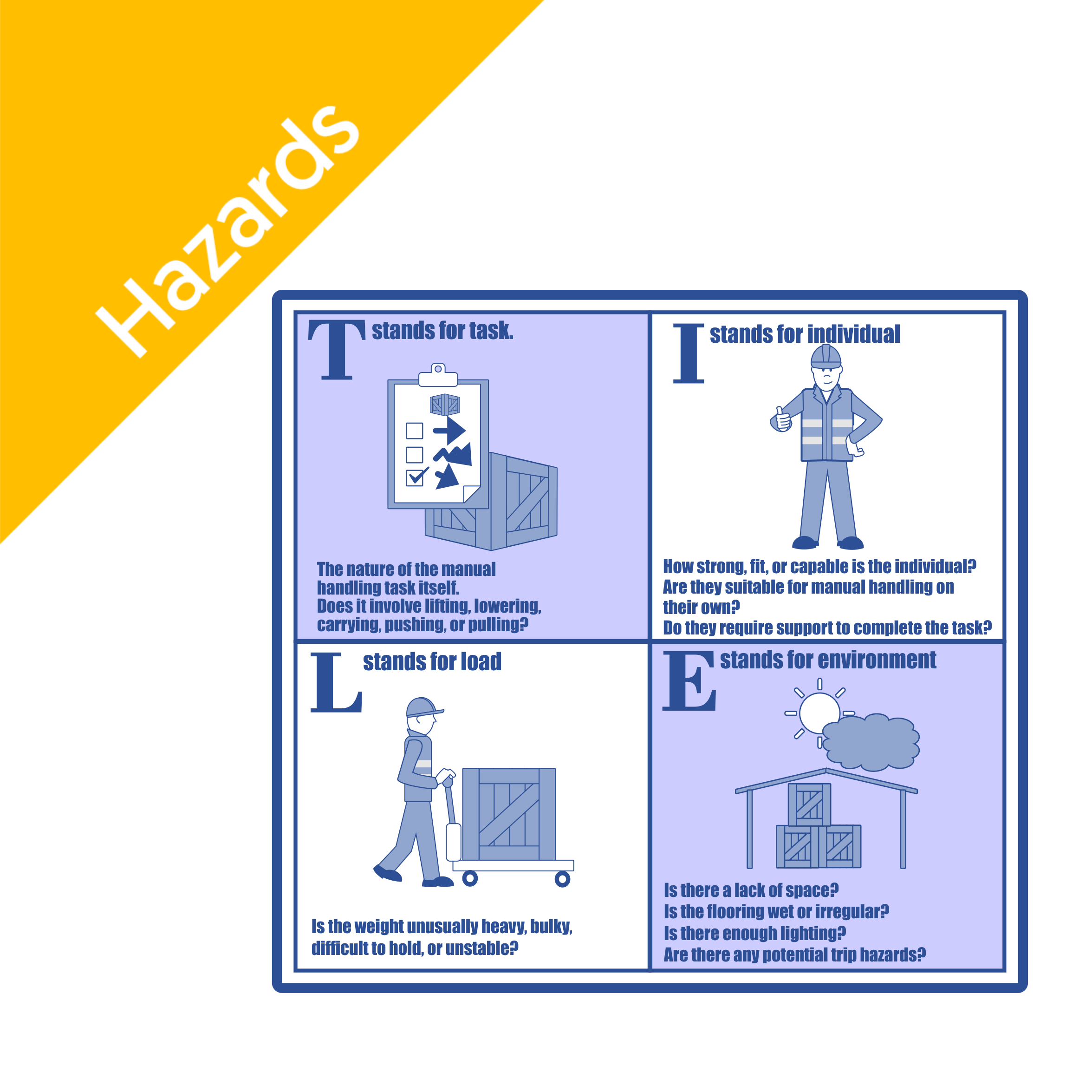

A simple way to assess tasks is by using TILEO.

TILEO Explained: Task, Individual, Load, Environment, Other Factors

TILEO is used to evaluate manual handling risks:

Task: Does the task involve twisting, bending, or long carrying distances?

Individual: Is the person trained, capable, and physically suited to the task?

Load: Is it heavy, awkward, unstable, sharp, or hard to grasp?

Environment: Is the space cramped, uneven, or poorly lit?

Other Factors: PPE requirements, time pressures, weather, or equipment issues.

Learn more in our guide: What Does TILEO Stand For?

Essential Safe Manual Handling Techniques

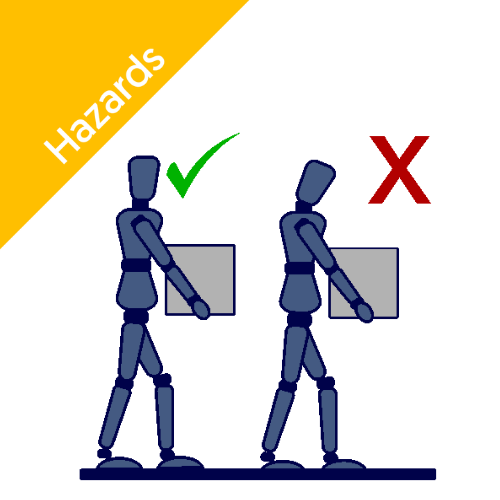

Safe lifting techniques reduce strain on muscles and joints. Key principles include:

Keep a straight back and bend your knees

Hold the load close to your body

Avoid twisting—move your feet instead

Push rather than pull when moving loads

Know your limits and ask for help with heavy or awkward loads

Mechanical aids such as sack trucks, trolleys, pallet trucks, and hoists should be used whenever possible.

See: Manual Handling Weight Limits

And: Manual Handling Equipment: Practical Guide

Conclusion

Safe manual handling is about understanding risks, applying the right controls, and using appropriate training and equipment. By following MHOR, conducting risk assessments, and embedding safe techniques, organisations can greatly reduce injuries and create a safer workplace.

Frequently Asked Questions

What does UK law require for manual handling at work?

Employers must avoid hazardous manual handling where possible. If tasks cannot be avoided, they must be risk assessed and controlled under applicable work regulations. These duties are set out in the Manual Handling Operations Regulations 1992 (MHOR).

Who is responsible for manual handling safety?

Employers have the primary responsibility for risk assessment, training, and safe systems of work. Employees must follow training and use equipment correctly.

Where can I find official guidance?

The Health and Safety Executive (HSE) provides official UK guidance on manual handling, risk assessments, and MHOR compliance.