What is workplace dust, and where does it come from?

Workplace dust is made up of tiny solid particles released whenever materials are cut, ground, handled, or abraded. These particles often form a dust cloud that can spread throughout a work area.

Examples of common dust sources:

Sawing or sanding timber (wood dust)

Grinding, welding, or blasting metals (metal dust)

Cutting or drilling concrete (silica dust)

Trimming or sanding composites (fibreglass and carbon fibre dust)

Sweeping floors or disturbing settled dust (resuspension)

Knowing the source of dust in your workplace helps you identify the hazards and select the right dust control measures.

What are the different types of dust in the workplace?

Dusts are often classified by composition. Each type has different properties and risks:

Type of Dust | Main Sources | Example Hazards |

|---|

Wood / MDF | Sawing, sanding, routing | Asthma, dermatitis, and nasal cancer |

Metal / Aluminium | Welding, grinding, blasting | Toxicity, lung damage, fire/explosion |

Concrete / Chalk | Cutting, drilling, crushing | Silicosis, lung cancer, and respiratory irritation |

Fibreglass / Carbon fibre | Fabrication, trimming | Skin irritation, allergic reactions, and respiratory issues |

Let’s look at each in more detail.

What are the hazards of wood and MDF dust?

Wood dust is a common hazard in carpentry and furniture making. Risks depend on the type of wood:

Hardwoods are linked to nasal cancers.

Western red cedar can trigger occupational asthma.

Softwoods may cause irritation and dermatitis.

MDF dust is particularly dangerous because it contains chemical resins and very fine particles, making it more likely to reach deep into the lungs.

Health risks include:

Eye, nose, and throat irritation

Reduced lung function and asthma

Increased cancer risk with long-term exposure

Because wood and MDF dusts are so easily inhaled, extraction systems and RPE (respiratory protective equipment) are essential.

What are the dangers of metal and aluminium dust?

Metal dust is created by machining, blasting, welding, and cutting. Aluminium dust is particularly hazardous because it is combustible and can cause explosions in confined spaces.

Health risks include:

Lung irritation and respiratory problems

Toxicity from certain metals (e.g. lead, nickel, cobalt)

Fire and explosion hazards

Controlling metal dust requires LEV systems, dust collectors, and safe handling practices to reduce accumulation.

Concrete and Chalk Dust

Concrete and chalk produce large amounts of fine dust during cutting, drilling, and crushing. Concrete dust often contains respirable crystalline silica (RCS), which is a leading cause of silicosis and lung cancer.

Industries most at risk: construction, tunnelling, and stone cutting.

Hazards include:

Silicosis (progressive and irreversible lung disease)

Chronic obstructive pulmonary disease (COPD)

Lung cancer from long-term exposure

Even short-term exposure can cause headaches, coughing, and irritation.

Fibreglass and Carbon Fibre Dust

Fibreglass and carbon fibre dusts are common in industries using composite materials, such as aerospace and automotive.

Risks include:

Skin irritation and rashes

Allergic reactions and respiratory problems

Eye and throat irritation

Carbon fibre dust is especially hazardous due to its sharp, fine particles, which penetrate deep into the respiratory tract. Protective clothing, gloves, and RPE are essential.

What health problems are caused by dust exposure at work?

Dust exposure affects mainly the respiratory system, but also the skin and eyes.

Short-term symptoms:

Coughing and shortness of breath

Eye, nose, and throat irritation

Headaches and fatigue

Long-term health effects:

Asthma and hypersensitivity pneumonitis

Silicosis, asbestosis, or COPD

Cancers of the lungs, nose, and sinuses

Early recognition of symptoms is critical. Workers should report issues quickly so exposure can be reduced. To learn more about the health risks, see our Knowledge Bank article Can You Get Sick From Dust Inhalation.

Which dusts are combustible, and why are they dangerous?

Some dusts are not only harmful to breathe but also explosive. A combustible dust can ignite if it disperses in the air and meets a heat source.

High-risk combustible dusts include:

Warning signs:

Fine, dry dust that disperses easily

Dust clouds in enclosed spaces

Build-up of dust on beams, ducts, or machinery

An ignition can cause a primary explosion, which often shakes loose more dust and leads to a much more destructive secondary explosion.

What UK regulations cover dust hazards in the workplace?

In the UK, dust hazards are regulated by:

Employer duties include:

Conducting dust risk assessments

Installing and maintaining LEV and extraction systems

Providing Personal Protective Equipment (PPE) and training

Keeping accurate compliance records

Employees must also follow safety procedures, wear PPE, and report unsafe conditions.

What are effective dust control measures in the workplace?

Effective dust control combines engineering controls, safe practices, and personal protection.

Practical steps include:

Install LEV and dust collectors close to dust sources

Use wet cleaning or HEPA vacuums instead of dry sweeping

Provide and maintain PPE such as masks, gloves, and goggles

Inspect and clean hidden areas where dust accumulates

Train staff on dust hazards and safe practices

Regular air quality monitoring and equipment checks ensure systems remain effective.

How do you perform a dust risk assessment at work?

A dust risk assessment helps employers identify where dust hazards exist, who may be at risk, and what control measures are needed.

Steps for carrying out a dust risk assessment:

Identify sources of dust – List the processes, tasks, and materials that generate dust (e.g. cutting concrete, sanding MDF, welding metals).

Determine the type of dust – Assess whether it is wood, silica, metal, or another hazardous dust.

Measure dust levels – Compare exposure against Workplace Exposure Limits (WELs).

Identify who may be exposed – Consider employees, contractors, and visitors.

Assess frequency and duration – Record how often and for how long people are exposed.

Evaluate existing controls – Check extraction systems, PPE, and safe working practices already in place.

Note environmental factors – Look at ventilation, confined spaces, and whether dust can travel off-site.

Document findings – Record risks, control measures, and any improvements needed.

Assign responsibilities – Make clear who will implement each control.

Review regularly – Revisit after changes in process, materials, or equipment.

For a practical tool to get started, see our [dust risk assessment PDF] and [dust control checklist] (links coming soon).

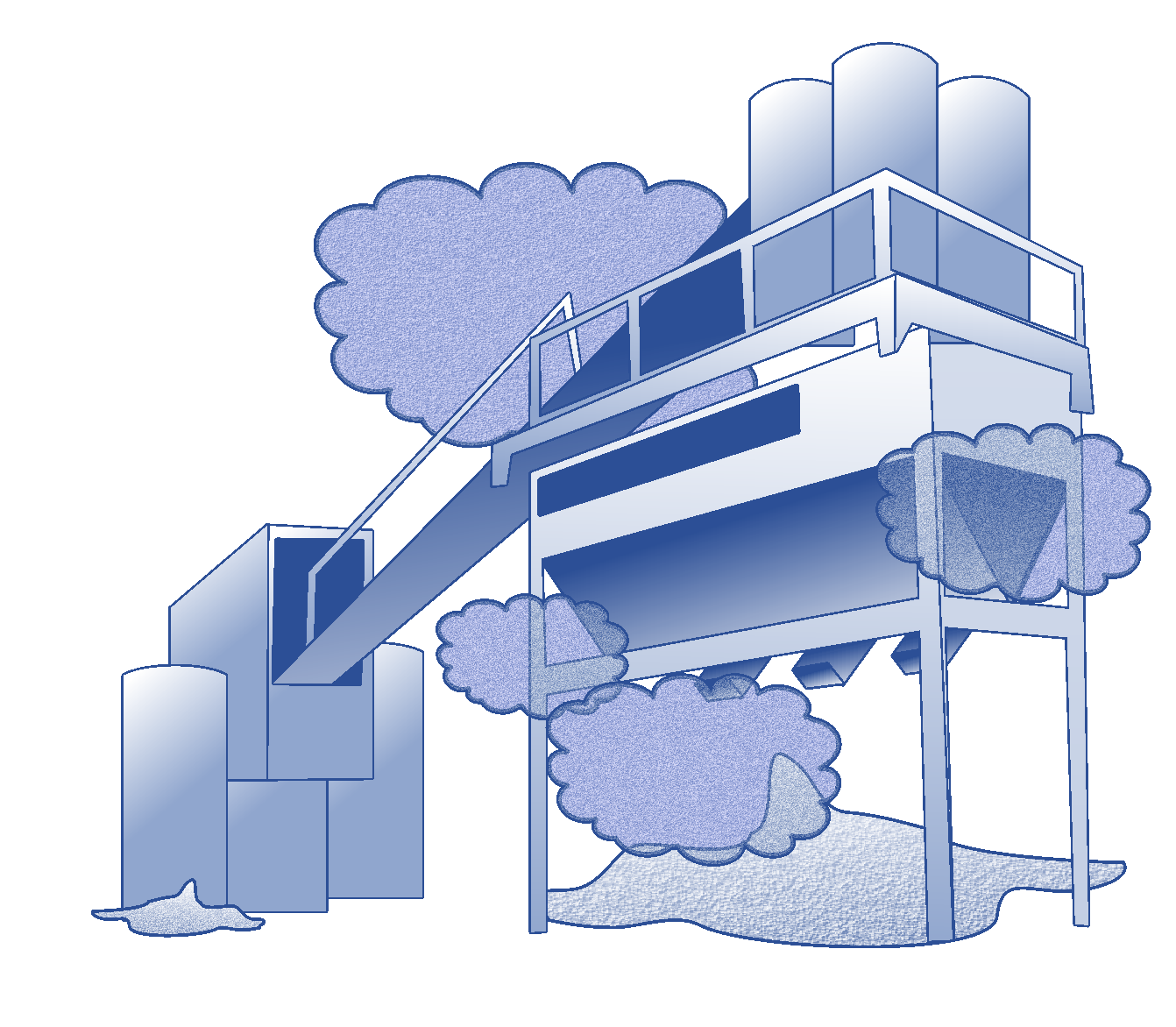

What dust control systems can employers use?

Modern workplaces can use a combination of engineering systems and monitoring technologies to manage dust effectively. These not only reduce worker exposure but also help demonstrate compliance with HSE requirements.

Common dust control systems and technologies include:

Local exhaust ventilation (LEV): Extracts dust directly at the source before it can spread into the air.

Enclosure systems: Isolate dusty processes in separate areas to reduce exposure.

Wet dust suppression systems: Spray water onto tools or surfaces to prevent dust clouds from forming (e.g. during cutting).

Personal dust monitors: Wearable devices that track individual worker exposure over a shift.

Fixed dust monitors: Installed in high-risk areas to measure airborne dust concentrations in real time.

Particle counters: Detect and measure fine airborne dust instantly.

Data logging software: Records dust exposure data, supporting audits and regulatory compliance.

For more practical guidance, you’ll soon be able to download our [dust control measures checklist] to help evaluate which systems are most suitable for your workplace.

High-Risk Industries and Examples

Sectors most at risk of dangerous dust exposure include:

Construction – silica dust from cutting concrete and stone

Woodworking – hardwood and MDF dust in furniture factories

Metal fabrication – aluminium and other metal dusts

Textiles - cotton, wool, and synthetic fibre dust from spinning, weaving, and cutting fabrics

Conclusion

Dust in the workplace is more than a nuisance; it can be toxic, carcinogenic, or explosive. Each dust type, from wood and MDF to silica, metal, and composites, poses different risks.

By following the hierarchy of control — eliminate, substitute, control at source, change practices, and use PPE — employers can significantly reduce dust hazards. Compliance with UK regulations, regular training, and early recognition of symptoms are key to protecting health and safety.