What Is Textile Dust?

Textile dust is produced whenever fibres are handled or processed. Cotton particles, in particular, are associated with byssinosis, a form of obstructive pulmonary disease that can lead to irreversible lung damage. Wool particles can cause chronic bronchitis, rhinitis, and eye irritation.

Even when exposure to particulate matter is below Workplace Exposure Limits, all reasonably practicable measures should be taken to reduce the amount of dust generated.

WELs for textile particles:

Type | WEL (8-hr TWA) |

|---|

Cotton | 2.5 mg/m³ |

Wool process | 10 mg/m³ |

You can learn more about Workplace Exposure Limits and COSHH requirements in our dedicated Dust Control Measures guide.

Health Hazards

Respiratory Diseases

Cotton dust exposure can cause byssinosis, which may have both acute and long-term effects. Early symptoms include chest tightness, coughing, and shortness of breath. Chronic exposure may lead to irreversible obstructive lung disease.

Wool dust is linked to chronic bronchitis, breathlessness, persistent rhinitis, and conjunctivitis. The risk increases with dust concentration and the duration of exposure.

Other Hazards

Dust explosions: Fine dust accumulation in dry areas can create combustible environments.

Dyestuff dust: Dust from dyes used in textile finishing can irritate the respiratory system if not handled under controlled conditions.

Endotoxin exposure: Certain cotton textile workers may be exposed to endotoxins, which can exacerbate respiratory symptoms.

You can also explore how dust forms in other sectors in our comprehensive Dust at Work FAQ.

Controlling Textile Dust

1. Engineering Controls

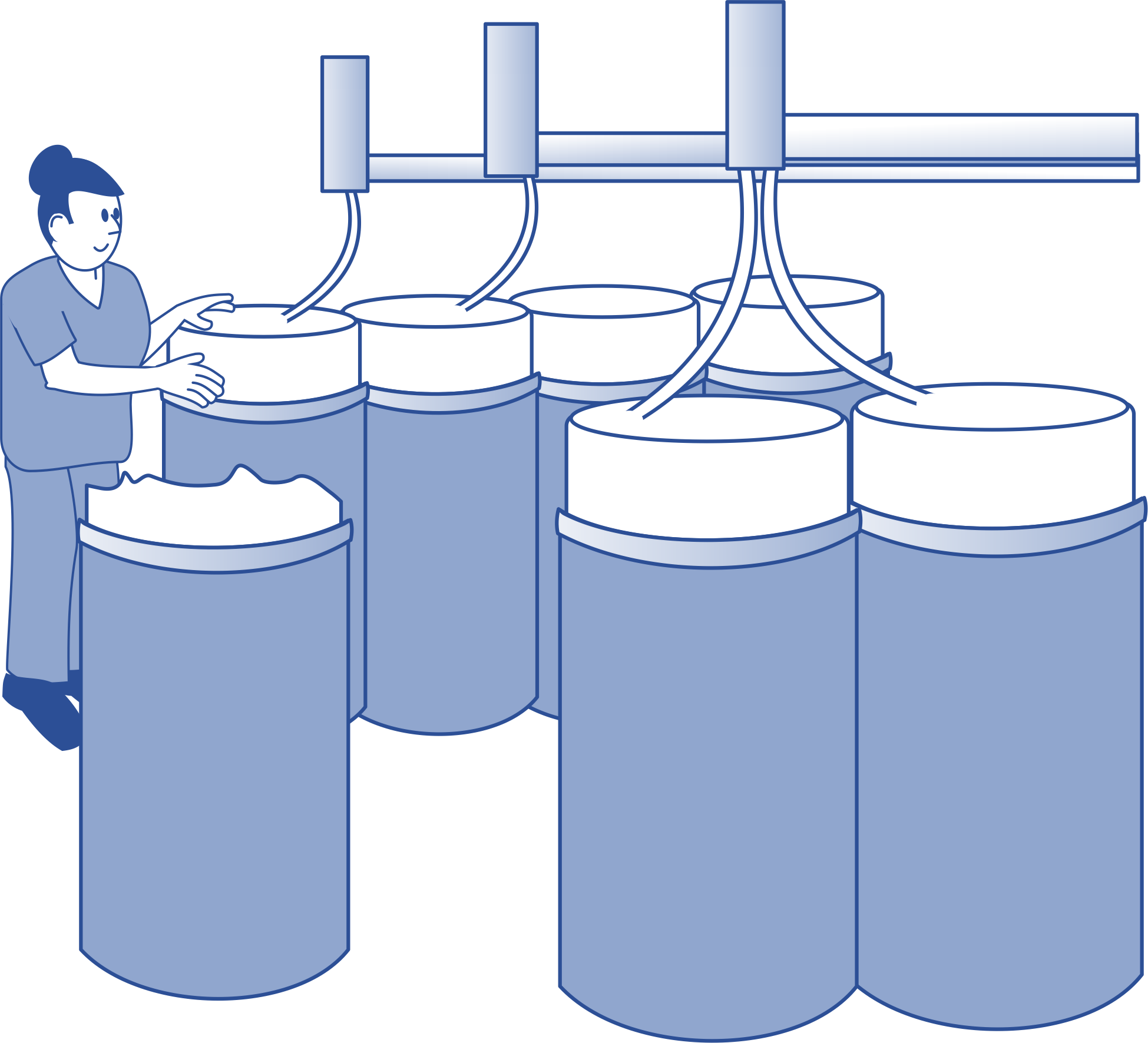

Local Exhaust Ventilation (LEV): Enclose machinery wherever possible, with LEV at essential openings to remove dust at the source.

Enclosure: Fully enclosing machinery reduces airborne dust and protects workers.

Automation: Minimise manual handling of raw materials, particularly at blending bins. Vacuum conveyor systems or automated bale pluckers can significantly reduce exposure.

General Ventilation: Helps maintain air quality and prevent high background dust levels.

Dust Collection Maintenance: Dust collectors and dust collection systems must be regularly inspected, emptied safely, and maintained to ensure the lowest level of dust in the workplace.

2. Safe Work Practices

Avoid sweeping, brushing, or using compressed air.

Use Type H industrial vacuum cleaners or piped vacuum systems.

Lightly moisten floors if brushing is unavoidable.

Reduce dust from dyestuffs by using low-dust forms, such as solutions, granules, pastes, or pre-weighed powders.

3. Personal Protective Equipment (PPE)

Respiratory Protection: FFP2/FFP3 or powered visor respirators with proper fit-testing protect against airborne matter.

Protective Clothing: Close-weave or disposable coveralls, gloves, and aprons prevent secondary contamination.

Eye Protection: Safety glasses are essential when handling dyestuffs or during processes that generate fine particles.

Training, Awareness, and Compliance

Emplyers in the textile industry should ensure:

Workers understand occupational exposure risks from cotton and wool particles.

Training for the correct use of LEV, PPE, and dust collection systems.

Maintenance and inspection protocols are clearly communicated, with defects reported immediately.

Health surveillance is conducted regularly to help identify early respiratory symptoms and prevent occupational lung disease.

You can also strengthen workplace safety by completing our online Dust Awareness Course and COSHH Training.

Conclusion

Textile dust is more than a nuisance; it is a recognised occupational hazard that can lead to occupational respiratory disease, byssinosis, and other health complications. By combining engineering controls, effective housekeeping, proper PPE, and ongoing training, mills can protect textile workers from long-term harm.

Key strategies include:

Enclosure of machinery and LEV systems

Minimising manual handling and automating where feasible

Housekeeping using Type H vacuum cleaners

Correct use and maintenance of PPE

Health surveillance and worker training

Reducing textile dust exposure ensures workplace safety, compliance with occupational exposure limits, and protection of employees’ long-term respiratory health.

For further support on managing workplace dust, explore our main Dust at Work topic article, our Dust at Work FAQ, and our comprehensive guide on dust control measures.

Frequently Asked Questions about Textile Industry Dust

What is textile dust?

Textile dust is generated during the handling and processing of fibres such as cotton and wool. It includes fine airborne dust from raw cotton, spinning, carding, blending, and finishing processes.

Why is textile dust dangerous?

Breathing in textile dust over time can damage the respiratory system. Cotton dust may cause byssinosis and irreversible obstructive lung disease. Wool dust can trigger chronic bronchitis, rhinitis, and eye irritation. Dust can also create combustible conditions if it accumulates.

Which processes produce the most dust?

Cotton: Raw cotton handling, opening, carding, drawing, combing, ring spinning, high-speed winding.

Wool: Opening, blending, carding, backwinding, willying processes.

What are the legal exposure limits in the UK?

How can dust exposure be reduced?

Dust exposure can be reduced when workplaces:

Use LEV and dust collection systems.

Enclose machinery and automate manual handling.

Maintain good air quality through ventilation.

Process dusty batches in controlled areas.

How should textile dust be cleaned?

The best way to clean textile matter is to:

Avoid sweeping, brushing, or compressed air.

Use Type H vacuums or piped vacuum systems.

Moisten floors when brushing is unavoidable.

Do textile workers need PPE?

Yes, PPE is essential when particulate matter cannot be fully controlled: respirators, coveralls, gloves, aprons, and eye protection.

What is byssinosis?

Byssinosis, or “brown lung disease,” is a chronic respiratory disease caused by cotton dust exposure. Early symptoms include chest tightness, coughing, and wheezing.

Is wool dust less harmful than cotton dust?

Wool dust causes respiratory irritation but does not typically result in byssinosis. Controls and PPE are still required.

Can dust explosions occur in textile mills?

Yes, fine dust accumulation in dry areas can be combustible. Proper housekeeping, dust control, and ventilation mitigate the risk.

Where can I find more guidance?

Official government organisations such as HSE guide COSHH, occupational exposure limits, and occupational safety.

Industry-specific guidance for cotton textile workers and wool processing.

Secure websites from national institutes and occupational health authorities, including the World Health Organization.