Even small amounts of dust inhaled over a workday, repeated day after day, can accumulate in the lungs and contribute to serious health problems. Recognising the types of dust and understanding the health risks is the first step toward effective protection.

Types of Dust Commonly Found in the Construction Industry

Construction dust can be categorised into three main types:

Type of Dust | Source Materials | Health Risk |

|---|

Silica Dust (RCS) | Concrete, mortar, sandstone | High risk; can cause silicosis, lung cancer |

Wood Dust | Softwood, hardwood, MDF | Respiratory irritation, asthma, and rare cancers |

Lower Toxicity Dusts | Gypsum, limestone, marble, dolomite | General irritation, lower risk, but cumulative effects are possible |

Even when using materials with lower toxicity, the accumulation of dust over a long time can contribute to chronic respiratory diseases. For construction workers, continuous exposure without proper controls can result in permanent disability or early death.

Health Risks from Dust Exposure

The health issues associated with construction dust vary depending on the type and amount of dust, the duration of exposure, and individual susceptibility. Short-term exposure to high dust levels can cause immediate irritation of the eyes, nose, throat, and lungs. Long-term exposure, however, is far more dangerous and insidious.

Breathing in silica dust over many years is particularly dangerous. Silica particles are fine enough to penetrate deep into the lungs, causing scarring that leads to irreversible conditions like silicosis. Workers exposed to dust from different materials over a long time may also develop chronic respiratory diseases, such as COPD, and are at increased risk of early death.

To understand more about the health risks associated with dust, read our Can you get sick from dust inhalation? article.

Legal Requirements for Dust Control

In the UK, employers are legally obliged to manage dust hazards under the Control of Substances Hazardous to Health (COSHH) Regulations. These regulations require employers to assess, control, and review dust risks regularly. This includes identifying high dust areas, evaluating the types of dust involved, and implementing the right controls.

The steps required by COSHH include:

Assessing the work area, construction tasks, and materials to determine dust hazards.

Controlling exposure using measures such as water suppression, extraction units, and respiratory protection.

Reviewing controls to ensure they are effective over time, particularly when tasks, materials, or dust levels change.

Employers must also provide appropriate training so workers understand the risks of dust and how to use controls effectively. The Construction Dust Partnership provides industry-wide guidance and training resources to support safer work practices Construction Dust Partnership.

Practical Measures to Reduce Dust Exposure

Construction Dust Engineering Controls

The most effective way to reduce dust exposure is to control it at the source. This includes:

On-tool extraction units (LEV) fitted to grinders, sanders, and other power tools.

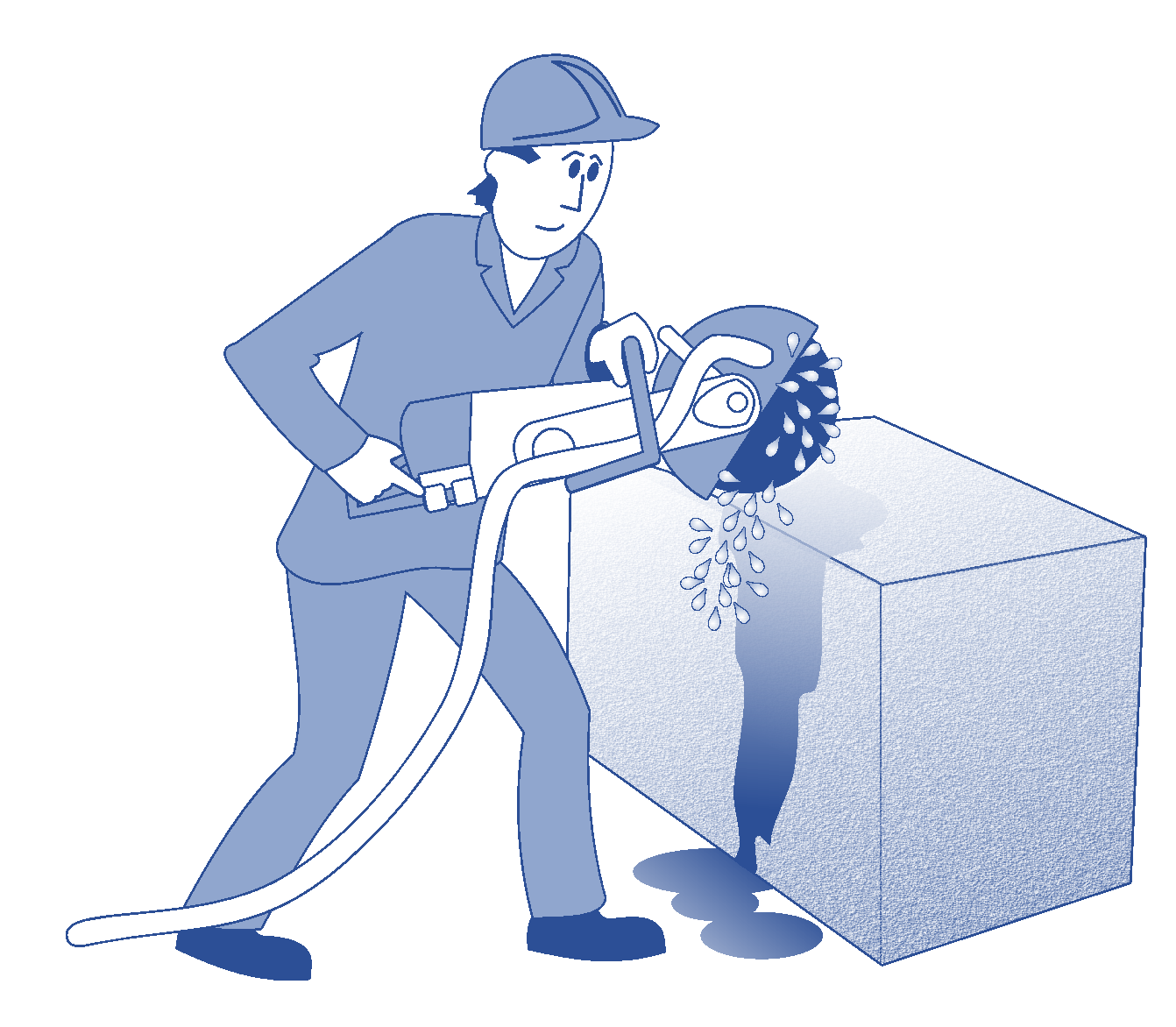

Water suppression, which dampens dust as it is created.

Using less powerful tools or adopting alternative methods to reduce dust generation.

By controlling dust at its source, you minimise the spread of dust clouds in the work area, lowering risk for everyone on site.

Safe Work Practices

In addition to engineering controls, safe work practices are crucial:

Avoid dry sweeping, which raises settled dust back into the air.

Use H or M class vacuum cleaners for site cleaning.

Dampen surfaces before cleaning or removing debris.

Cover skips and chutes to prevent dust escape.

H and M class vacuum cleaners are specialised types designed for hazardous dusts. H-class offering the highest level of filtration for the most dangerous materials. M-class vacuums are suitable for medium-risk dusts.

These general-level measures help maintain lower dust levels and reduce overall exposure during a workday.

Personal Protective Equipment: RPE

When dust levels remain high despite engineering controls, respiratory protection is essential. RPE is the last line of protection, but must be used correctly to be effective.

Key points for RPE use include:

Selecting the right type for the dust and task (Assigned Protection Factor, APF, indicates protection level).

Ensuring proper fit through face-fit testing.

Wear the equipment consistently for the duration of the task.

Maintaining and storing RPE correctly.

For construction workers using powerful tools like grinders or grit blasters, a higher-grade RPE with a suitable APF is critical. Remember, RPE is not a replacement for dust controls but a complementary measure to reduce risk.

Dust from Construction Training and Awareness

Proper training ensures that workers are aware of construction dust hazards and know how to implement the right controls. Employers must provide:

Information on the health risks of different dusts.

Guidance on using water suppression and extraction units.

Training on selecting, fitting, and maintaining RPE.

Instructions for reporting failures or problems with dust control systems.

The Construction Dust Partnership and the HSE’s construction dust guidance provide valuable resources to supplement on-site training.

Conclusion

Construction dust is a serious occupational health hazard that can cause chronic respiratory diseases, permanent disability, and even early death. Understanding the types of dust, the associated risks, and the correct controls is essential for every construction worker.

Effective strategies include:

Reducing dust at the source with water or extraction units.

Using proper work practices and cleaning methods to minimise dust clouds.

Wearing suitable respiratory protection when necessary.

Staying informed through ongoing training and awareness initiatives.

By combining engineering controls, safe work practices, and personal protection, construction workers can significantly lower risk and protect their long-term health.