Understanding Isocyanates in the Workplace

Isocyanates are reactive chemicals used to produce polyurethane products. They are found in coatings, sealants, foams, adhesives, and glues, and can be released into the air as vapours or aerosols during spraying, mixing, or curing processes.

Exposure can occur through inhalation or skin contact, particularly when less hazardous materials are not substituted or when protective measures are inadequate, highlighting the potential risks involved. The level of risk depends on the task, the length of the work, and the concentration of the chemical being used.

Industries Most Affected by Isocyanate Regulations

Certain sectors face higher risks because of how they use isocyanates. These include:

Motor vehicle repair (MVR) – especially vehicle spray painters, who work with two-pack paints.

Spray coating and finishing operations.

Foam production for insulation and furniture.

Printing and packaging industries use polyurethane-based inks and adhesives.

Employers in these industries must implement robust monitoring and health surveillance programmes to comply with COSHH and prevent exposure-related illness.

Employers and employees have specific duties under COSHH and UK REACH when it comes to hazardous substances. Read more about these obligations in our Isocyanates and the Law overview.

Health Risks of Isocyanate Exposure

Isocyanates are one of the leading causes of occupational asthma in the UK. They also damage the skin’s protective barrier, leading to dermatitis and other irritation.

Respiratory Sensitisation

Becoming sensitised to isocyanates means even tiny exposures can trigger a severe asthma attack. Common early symptoms include coughing, wheezing, or chest tightness, and individuals experiencing these symptoms should seek medical attention. Once sensitised, recovery is unlikely, and continued exposure may force an individual to leave their job permanently.

Skin and Eye Irritation

Contact with liquid or vapour forms can cause severe irritation, redness, itching, or inflammation. Prolonged or repeated contact leads to occupational dermatitis. Eye irritation and sore throats are also common early indicators that controls are not working effectively.

UK Legal Requirements for Isocyanate Monitoring

Under the Control of Substances Hazardous to Health (COSHH) Regulations 2002, employers must prevent or adequately control exposure to isocyanates. This means:

Completing a detailed risk assessment.

Using appropriate control measures (elimination, substitution, engineering, and PPE).

Conducting regular monitoring and health surveillance.

Keeping records and acting promptly when results indicate excessive exposure.

Failure to comply can lead to HSE enforcement action and improvement notices.

Monitoring results should feed directly into your risk management process. Learn how to identify, assess, and reduce workplace hazards in our Isocyanate Risk Assessment and Control Measures article.

Workplace Exposure Limits (WELs)

The HSE sets specific limits for airborne isocyanates:

Exposure Limit Type | Limit Value |

|---|

Long-term (8-hour TWA) | 0.02 mg/m³ |

Short-term (15 min STEL) | 0.07 mg/m³ |

These limits apply to all forms of airborne isocyanates, including aerosols and vapours. Exceeding them signals a breakdown in control and requires immediate investigation.

Effective Methods for Isocyanate Detection

To confirm that controls are working, employers must use both air sampling and biological monitoring.

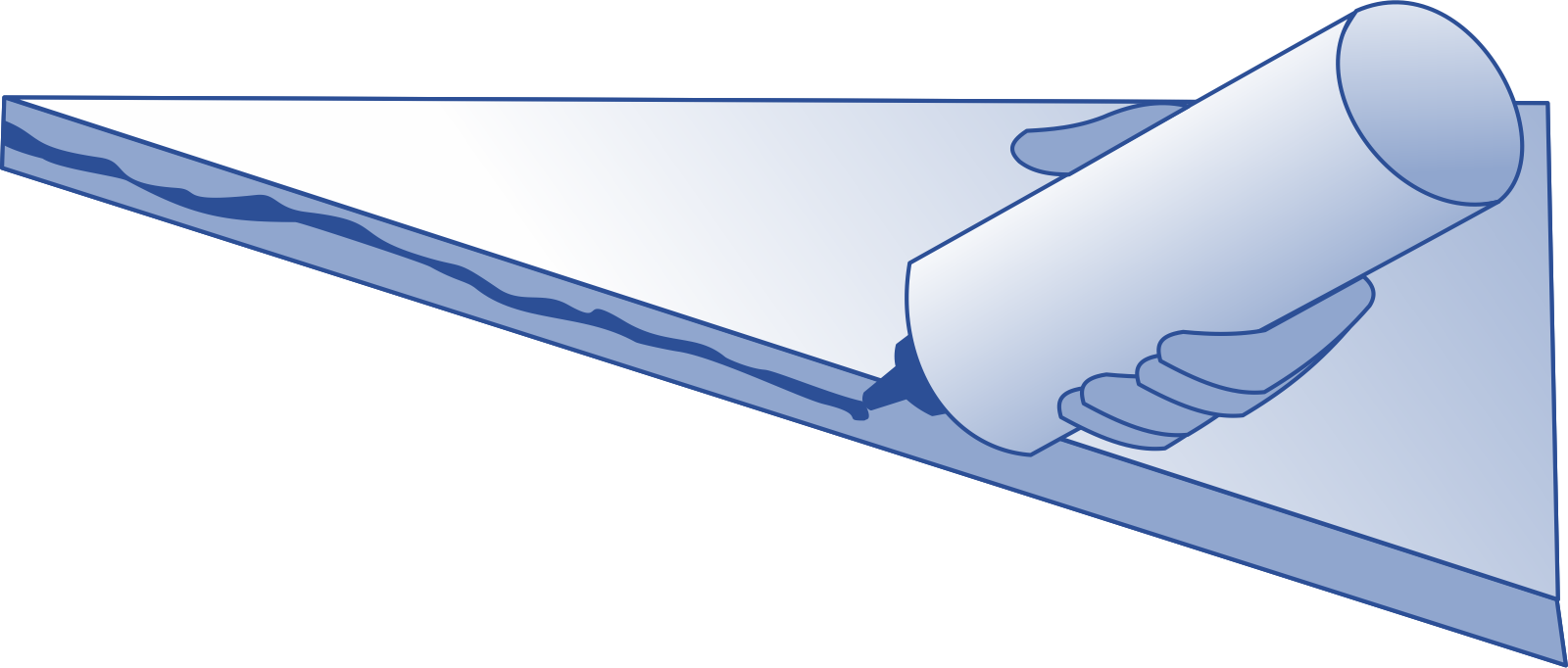

Air Sampling

Air sampling measures airborne concentrations during typical work activities. It involves collecting air from the breathing zone using constant flow air equipment. Results are compared against WELs to verify that ventilation and extraction systems are effective.

Biological Monitoring

This test measures metabolites of isocyanates in urine samples. It identifies absorption through the lungs or skin and is often required for vehicle spray painters and other high-risk workers. The HSE recommends annual testing as part of routine health surveillance to ensure exposure does not exceed the cubic metre of air limits for isocyanates.

Monitoring Frequency and Recordkeeping

Monitoring frequency depends on your processes and level of risk:

High-risk roles (e.g. spray painting): at least annually.

When processes or materials change: immediately following the change.

Following abnormal results or complaints, act as soon as possible.

Employers must keep air monitoring records for 5 years and health surveillance records for 40 years, as required under COSHH.

Control and Prevention Strategies

Monitoring should work hand in hand with robust control measures. Employers should follow the hierarchy of control:

Elimination – Use less hazardous materials where possible.

Engineering controls – Install or upgrade ventilation or spray booths with LEV systems.

Safe work practices – Limit the length of the work and ensure correct handling.

Personal Protective Equipment (PPE) – Provide and maintain the correct gear.

For detailed guidance on training requirements and safe handling, visit our Safe Use of Isocyanates page.

Personal Protective Equipment

When elimination and engineering controls cannot remove risk, PPE becomes essential.

Use constant flow air-fed RPE with an Assigned Protection Factor (APF) of 40 or more.

Conduct fit testing for tight-fitting masks.

Wear chemical-resistant gloves, disposable coveralls, and eye protection.

Always refer to the product’s Safety Data Sheet (SDS) for specific PPE recommendations.

Responding to High Exposure Levels

If monitoring reveals elevated exposure:

Stop work immediately and remove affected workers from the area.

Investigate the cause of failure (equipment, PPE, or work practices).

Take corrective action — repair, replace, or retrain as needed.

Retest to ensure exposure levels return below WELs.

If symptoms of ill health are reported, seek medical assessment and review your risk assessment and controls before work resumes.

Professional Monitoring and Health Surveillance Services

Many UK businesses rely on specialist providers for workplace air sampling, biological monitoring, and health surveillance to mitigate exposure risk. These professionals help interpret results, recommend improvements, and ensure compliance with COSHH and HSE guidance. Regular external audits can also support evidence during HSE inspections or when renewing certification.

Conclusion

Isocyanate monitoring is an essential part of protecting your workforce. Regular air and biological testing, combined with effective ventilation and PPE, ensure that your controls are working and that your employees remain healthy.

By taking a proactive, evidence-based approach, you’ll meet legal obligations, prevent occupational asthma and dermatitis, and build a culture of safety in your workplace.

Frequently Asked Questions

Who requires isocyanate monitoring, and how often should isocyanate testing be done?

Workers in high-risk industries such as vehicle spray painting, foam manufacturing, or adhesive use require regular monitoring. Annual isocyanate testing is recommended, though frequency should be based on your COSHH risk assessment.

What actions should employers take if exposure levels are high?

Stop work immediately, investigate the cause, and take corrective measures. Review your risk assessment, ensure PPE is effective, and provide medical support if symptoms are present.

How can workers best protect themselves from isocyanate exposure?

Follow the hierarchy of control — prioritise engineering solutions and good ventilation, then rely on Personal Protective Equipment such as constant flow air-fed respirators and gloves. Always read the Safety Data Sheet (SDS) before use and maintain good hygiene to protect the skin’s barrier.

Further Reading