This guide explains who needs training, how to handle isocyanates safely, and the legal requirements under UK REACH and COSHH regulations.

Explore our comprehensive Isocyanates Knowledge Bank topic and related guides for more in-depth guidance.

Who Needs Isocyanate Training?

Any professional or industrial worker who uses or handles polyurethane adhesives, sealants, or foams containing diisocyanates must complete mandatory safety awareness training under UK REACH regulations. This requirement applies to all products with a diisocyanate concentration of 0.1% or more.

To determine if training is required:

Check the product label or safety data sheet (SDS) - these should indicate whether training is necessary.

For older products without clear labelling, confirm the diisocyanate content with the manufacturer.

Training is valid for a period set by the regulatory guidance and must be refreshed periodically to ensure ongoing safe use of these substances. Completing this training is essential for protecting workers from occupational asthma, respiratory disease, and other health hazards associated with isocyanate exposure.

Types and Levels of Training

Training is designed according to the worker’s role and level of exposure:

Basic Training (Level 1) – Awareness of health hazards and safe handling for general users.

Intermediate Training (Level 2) – Practical guidance for those applying PU adhesives, sealants, or coatings.

Advanced Training (Level 3) – For supervisors and industrial users overseeing multiple applications.

Industry-specific modules exist for construction, motor vehicle repair, carpentry, and industrial production. You can use the Safe Use Diisocyanates Matrix to determine the correct training level.

Access to training is available through FEICA, ISOPA, and ALIPA.

Commodious COSHH Awareness Training is also recommended, providing essential knowledge for all workers handling hazardous substances, including isocyanates, low molecular weight diisocyanates, and spray polyurethane foam.

Recognising Symptoms of Isocyanate Exposure

Early recognition is vital to prevent chronic health effects:

Short-term symptoms:

Cough, wheezing, or chest tightness

Irritation of eyes, nose, or throat

Skin redness, itching, or rash

Long-term effects:

Workers should report symptoms immediately and seek medical assessment. Early intervention reduces the risk of permanent harm.

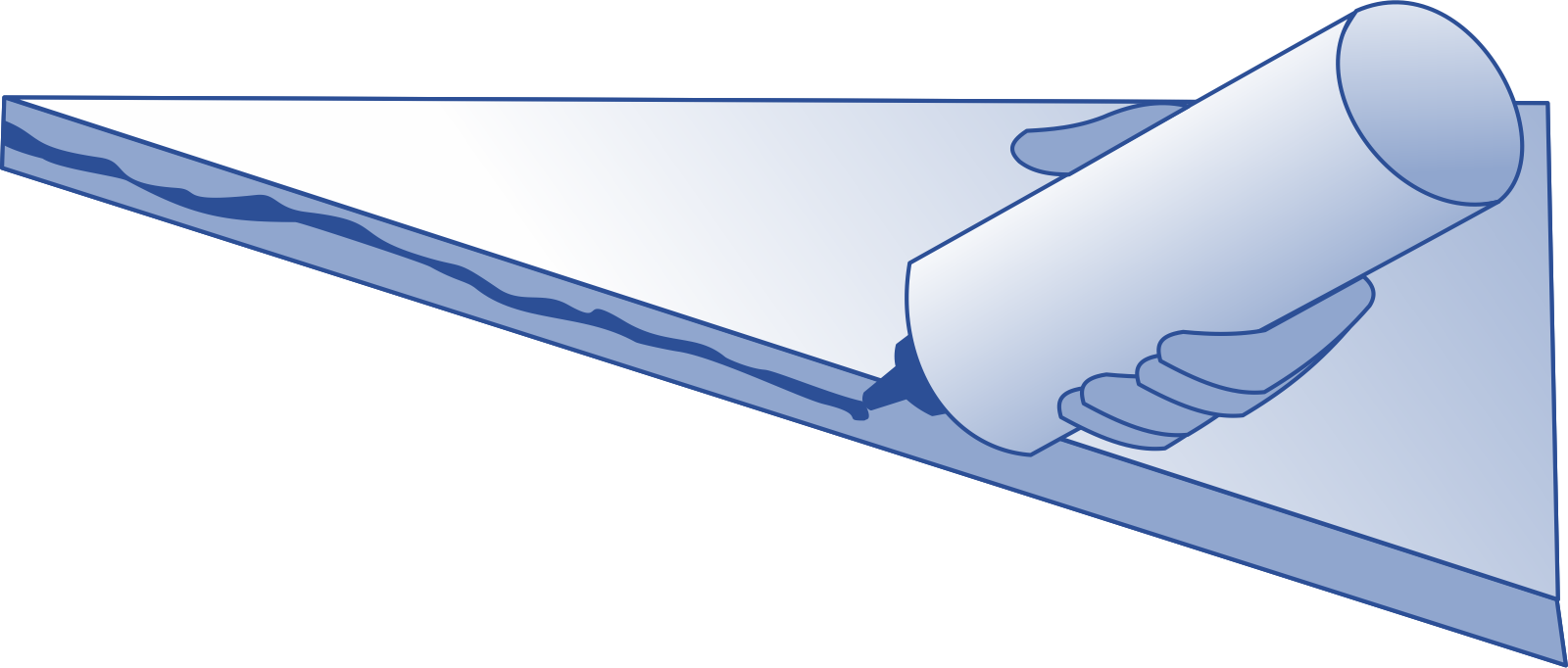

Safe Handling and Workplace Measures

Apply the hierarchy of control to minimise occupational exposure:

1. Elimination or substitution

2. Engineering controls

3. Work practices

Close spray booths during operation.

Allow clearance before re-entry.

Follow guidance for spray polyurethane foam or automotive coatings.

4. Personal Protective Equipment (PPE)

Air-fed respirators or supplied-air RPE for spraying tasks.

Chemical-resistant gloves, overalls, and eye protection.

5. Training and supervision

Spill Management

In case of a spill of isocyanates:

Evacuate the area and ensure adequate ventilation.

Wear appropriate PPE before handling the spill.

Use absorbent materials to contain and clean up.

Dispose of waste according to local regulations.

Report the incident to supervisors and review control measures to prevent recurrence.

We've written an in-depth guide to conducting a COSHH Risk Assessment and an article on control measures you can use to prevent isocyanate risks. See our knowledge bank articles for even more isocyanate guidance.

Biological Monitoring

Exposure monitoring is vital to assess exposure levels. Biological monitoring is especially important for workers handling low molecular weight isocyanates.

Understand isocyanate monitoring and why it is important by reading our Knowledge Bank article.

Legal Requirements

To understand employer responsibilities for dealing with isocyanates in the workplace with our guide to the Isocyanate Regulations UK.

Accidental Exposure: Steps to Take

If someone is accidentally exposed:

Leave the area and move to fresh air.

Remove contaminated clothing carefully.

Wash exposed skin with soap and water.

Seek medical attention immediately.

Report the incident and investigate to prevent future exposure.

Early recognition of symptoms, including coughing, eye irritation and skin rash, is critical to prevent long-term chronic health effects.

Integrating COSHH Training

Commodious COSHH Awareness Training equips workers and employers to:

Understand isocyanate health hazards and chronic health effects

Apply safe handling practices and PPE use

Conduct risk assessments and health hazard evaluations

Comply with legal requirements under COSHH and REACH

COSHH training provides a strong foundation for workers who also complete mandatory diisocyanate training.

Conclusion

Safe use of isocyanates depends on training, PPE, monitoring, and early reporting of symptoms. Employers and workers must follow best practices in workplace environments where polyurethane products are used, including motor vehicle repair, construction, and industrial plants.

Ensure your team completes:

Further Reading