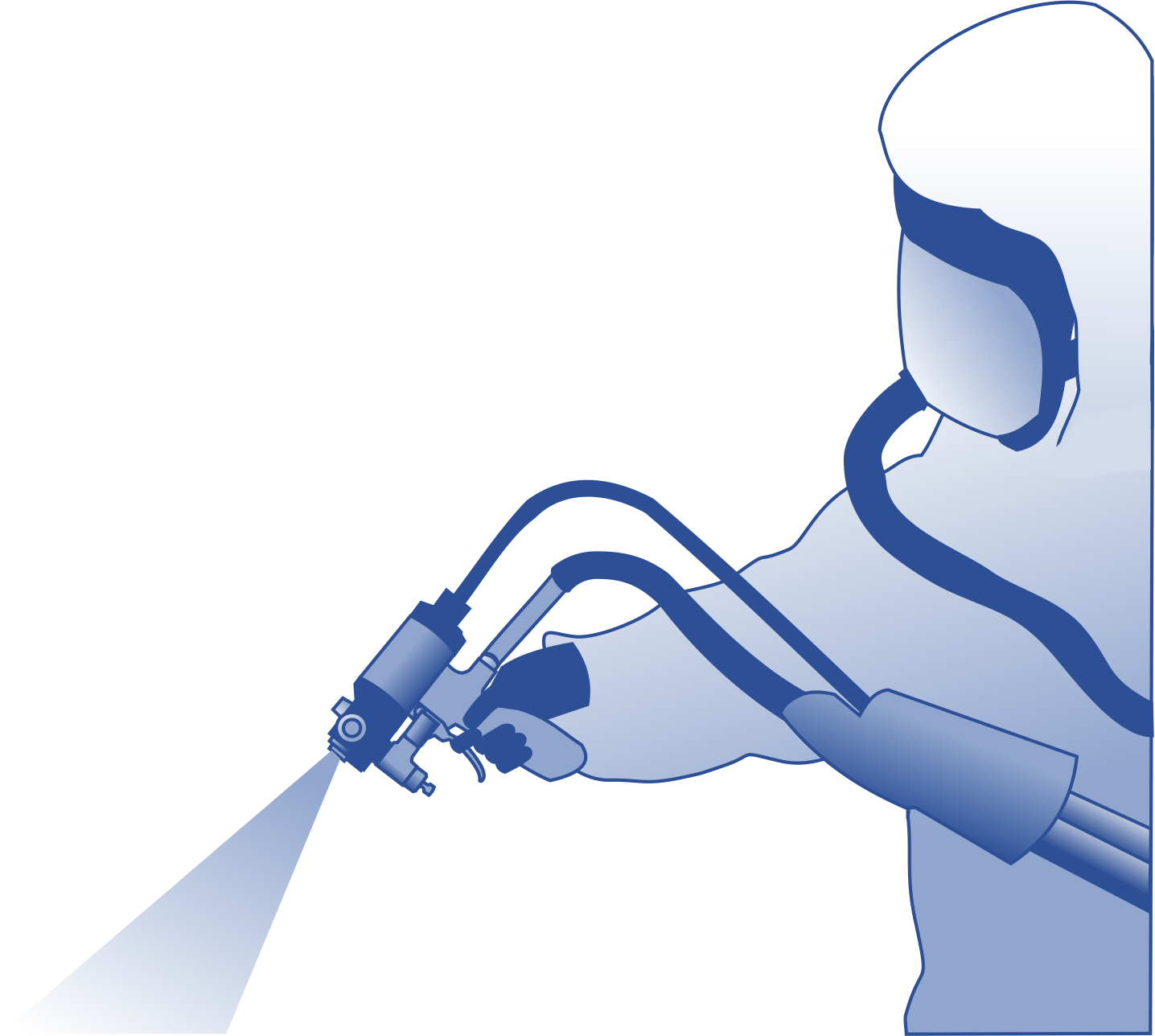

When sprayed, heated, or mixed, isocyanates release invisible vapours or fine mists that can be inhaled. Because they are often odourless, workers may not realise they are exposed to these respiratory hazards. Exposure can occur in both the workplace environment and during the production of polyurethanes.

Isocyanates and Diisocyanates: What’s the Difference?

Understanding the difference between isocyanates and diisocyanates helps identify which products carry the greatest risk of occupational exposure.

Isocyanates are chemical compounds containing one or more reactive -NCO groups, used in coatings, adhesives, and foams.

Diisocyanates are a subgroup of isocyanates containing two -NCO groups per molecule, making them highly reactive. These are often used in polyurethane production, spray polyurethane foam, truck bed liners, and high-performance coatings.

Common diisocyanates in the workplace include:

TDI (Toluene diisocyanate) – used in flexible foam and coatings

MDI (Methylene bisphenyl diisocyanate) – used in rigid foams and adhesives

HDI (Hexamethylene diisocyanate) – common in spray paints and automotive coatings

IPDI (Isophorone diisocyanate) – used in high-performance coatings and sealants

Naphthalene diisocyanate (NDI) – used in elastomers

Phenyl isocyanate and aryl isocyanates – used in specialised polyurethane applications

Most occupational exposure occurs from diisocyanate-based products, particularly in the automobile industry, motor vehicle repair, and during spray polyurethane foam application. All forms can cause respiratory disease, severe asthma, skin sensitisation, and inflammation of the mucous membranes of the eyes.

Health Risks of Isocyanates Exposure

Exposure can occur through inhalation or skin contact, causing both short- and long-term chronic health effects.

Short-term symptoms may include:

Irritation of the eyes, nose, throat, and mucous membranes

Coughing, wheezing, or breathlessness

Skin redness, itching, or rash

Long-term health effects:

Occupational asthma – often permanent; even small exposures can trigger respiratory disease after sensitisation

Dermatitis from repeated contact with isocyanate-containing products

Inflammation of the respiratory tracts and chronic respiratory disease

Workers who notice symptoms should report them immediately and seek medical advice. Case reports from the International Isocyanate Institute (ISI) highlight the importance of early intervention to prevent permanent damage.

What Should You Do if You Think You Have Been Exposed to Isocyanates?

Immediate action is essential to prevent severe asthma or other long-term health problems:

Leave the area and move to fresh air immediately.

Remove contaminated clothing carefully to avoid spreading chemicals.

Wash exposed skin thoroughly with soap and water.

Seek medical advice promptly, even if symptoms appear mild.

Inform your employer or supervisor to record and investigate the incident under COSHH.

Do not return to work involving isocyanates until medically cleared.

Early symptoms to watch for:

Cough, wheezing, or chest tightness

Shortness of breath

Eye or skin irritation

Red, itchy, or blistered skin

Employers should review control measures, respiratory protective equipment (RPE), and health surveillance following any suspected exposure.

Common Work Situations Involving Isocyanates Examples

Certain industries and tasks carry a higher risk of occupational exposure:

Motor vehicle repair and automobile industry: Spray painting, cleaning, or maintenance using 2K polyurethane paints

Construction: Applying spray polyurethane foam, coatings, adhesives, or sealants

Manufacturing and production of polyurethanes: Foam, elastomers, plastics, and furniture

Maintenance and cleaning: Handling equipment previously exposed to isocyanates

Spraying and mixing create airborne mists and vapours that can spread throughout the workplace environment.

Read more about the Safe Use of Isocyanates, training requirements and options.